Engine cylinder block processing and its process

2020-04-22

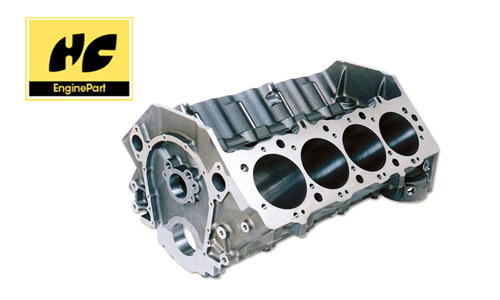

As a high-tech component of automobiles, the processing of engine blocks gradually penetrates into major enterprises. The engine block is a thin-walled and porous part, which requires extremely high precision for various processing procedures, and the quality of the part processing directly affects the performance of the engine.

The engine block is a box-like part with a thin-walled porous complex structure, which is easy to deform during its processing, which requires strict control of its accuracy. At present, the processing and production of engines mainly refer to the completion of production on flexible lines under the control of CNC machining centers. This technology has high requirements for automation technology and relatively low production costs. In addition, in the processing of the cylinder block, the accuracy of any link should be very high, otherwise it is difficult to meet the standard requirements of this process. The following is the specific technological process of cylinder processing:

1. Cylinder surface processing

The surface processing of the cylinder is mainly divided into plane processing and gap processing. The plane machining is mainly composed of end face milling, such as: processing the top face, the bottom and the front and rear faces. The processing of voids often requires processes such as boring, honing, drilling, reaming, and tapping, including water jacket hollowing, mounting holes, connecting holes, piston cylinder holes, oil holes, etc.

2. Cylinder machining process

The machining process of the cylinder block can be roughly divided into four programs: main profile processing, main hole column processing, cleaning inspection, and auxiliary structure processing. Different programs are responsible for different fields and different positioning standards. For example: part of the program adopts the two-pin full positioning method, and some adopts the rough reference 3 one 2 one] full positioning method. Moreover, the positioning surface in different ways also has a difference between the bottom surface and the end. In the machining process of the cylinder block, it is an extremely important process for the machining of the bottom and end surfaces of the cylinder block.

3. Cylinder machining division stage

Cylinder machining can be divided into two modules, roughing and finishing. Each module can be divided into two parts. The entire production line is divided into three parts: roughing unit, semi-finishing unit and finishing unit. For each stage, the product needs to be positioned according to the demand and rationalized production should be carried out.