Crankshaft flywheel

2020-04-14

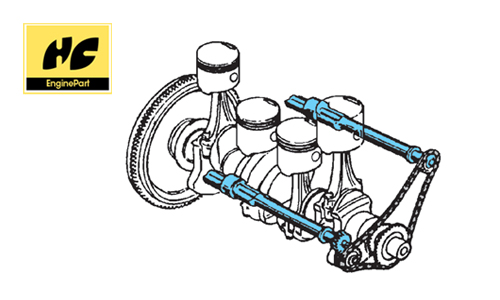

1 The role and materials of the flywheel

The flywheel is a disk with a large moment of inertia. Its main function is to store part of the kinetic energy input to the crankshaft during the power stroke to overcome the resistance in other strokes and drive the crank connecting rod mechanism to cross the top dead center and the bottom The dead point ensures that the rotation angular velocity and output torque of the crankshaft are as uniform as possible, and makes it possible for the engine to overcome the overload in a short time. In addition, in terms of structure, the flywheel is often used as the driving member of the friction clutch in the automobile transmission system.

The flywheel is mostly made of gray cast iron. When the linear speed of the rim exceeds 50m / s, it is made of ductile iron or cast steel with higher strength.

2 Structure of the flywheel

A gear ring is pressed on the outer edge of the flywheel, which can be meshed with the drive gear of the starter for use when starting the engine. The first cylinder ignition timing mark is usually engraved on the flywheel in order to calibrate the ignition time. The mark on the flywheel of Dongfeng EQ6100-1 engine is an embedded steel ball.

The flywheel of a multi-cylinder engine should be dynamically balanced together with the crankshaft, otherwise the centrifugal force due to weight imbalance during rotation will cause engine vibration and accelerate the wear of the main bearings. In order not to destroy their equilibrium state during disassembly and assembly, there must be a strict relative position between the flywheel and the crankshaft, and it is guaranteed by positioning pins or asymmetrically arranged bolts.