Reasons for the tightness of the engine cylinder head seal Part 1

2020-06-08

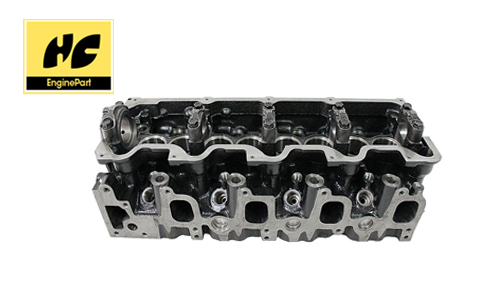

The quality of the cylinder head sealing performance has a great influence on the technical status of the engine. When the cylinder head is not tightly sealed, the cylinder will leak air, resulting in insufficient compression pressure of the cylinder, lower temperature and lower air quality. When the air leakage of the cylinder is serious, the engine power will be significantly reduced, and even it will not work. The main reasons affecting the sealing performance of the engine cylinder head are listed below.

1. Incorrect use and installation of cylinder head gasket

The cylinder gasket is installed between the engine cylinder block and the cylinder head. Its function is to ensure the sealing of the combustion chamber and prevent the leakage of gas, cooling water and lubricating oil. Therefore, the unsuitable use and installation of the cylinder head gasket directly affects the sealing reliability of the cylinder head and the service life of the cylinder head gasket. In order to ensure the sealing quality, the selected cylinder gasket must be the same size and thickness as the original cylinder, the surface should be flat, the edge is tightly bonded, and there are no scratches, dents, wrinkles and rust. Otherwise, it will affect the sealing quality of the cylinder head.

2. Slight runout of cylinder head

The slight jump of the cylinder head is the result of the cylinder head trying to separate from the cylinder block under the effect of compression and combustion pressure. These pressures lengthen the cylinder head connecting bolts, thus causing a slight jump of the cylinder head relative to the cylinder block. This slight bounce will cause the cylinder head gasket to relax and compress, thereby speeding up the damage of the cylinder head gasket and affecting its sealing performance.

3. The connecting bolt of the cylinder head does not reach the specified torque value

If the cylinder head connecting bolts are not tightened to the specified torque value, the wear of the cylinder head gasket caused by this slight jump will occur faster and more severely. If the connecting bolt is too loose, it will cause the amount of runout of the cylinder head relative to the cylinder block to increase. If the connecting bolt is over-tightened, the stress of the connecting bolt will exceed its yield strength limit, resulting in the lengthening of the connecting bolt exceeding its design tolerance, which will also cause the jump of the cylinder head to increase To accelerate the wear of the cylinder head gasket.

4. The flatness of the cylinder head or cylinder block is too large

Warpage and distortion are common problems in cylinder heads and the main cause of repeated burning of cylinder head gaskets. In particular, the aluminum alloy cylinder head performs more prominently, because the aluminum alloy material has a high heat transfer efficiency, and the cylinder head is smaller and thinner than the cylinder block, and the temperature of the aluminum alloy cylinder head rises fast . When the cylinder head is deformed, its planar engagement with the cylinder block will be less rigid, and the sealing quality of the cylinder will decline, causing air leakage and burning out the cylinder gasket, thereby further deteriorating the sealing quality of the cylinder.