Ukuchezuka okuhlelekile okuhlobene nomshini kwamathuluzi omshini kungarekhodwa ngokuhlelekile, kodwa ukuchezuka kusengavela noma kwande ngesikhathi sokusetshenziswa okulandelayo ngenxa yezimo zemvelo ezifana nezinga lokushisa noma umthwalo wokusebenza. Kulezi zimo, i-SINUMERIK ingahlinzeka ngemisebenzi ehlukene yesinxephezelo. Unxephezela ukuchezuka usebenzisa izilinganiso ezisuka kuzifaki khodi zendawo (isb. ama-gratings) noma izinzwa ezengeziwe (isb. ama-laser interferometer, njll.) ukuze uthole imiphumela engcono yokwenza imishini. Kulolu shicilelo, sizokwethula imisebenzi evamile yesinxephezelo ye-SINUMERIK. Imijikelezo yokulinganisa ye-SINUMERIK esebenzayo efana ne-"CYCLE996 Motion Measurement" inganikeza ukusekelwa okuphelele kubasebenzisi bokugcina ngesikhathi sokuqapha nokugcinwa okuqhubekayo kwamathuluzi omshini.

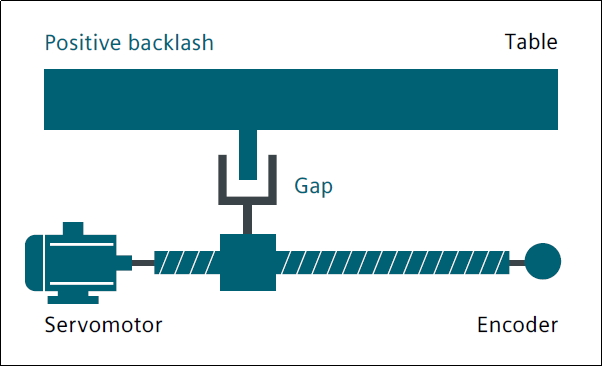

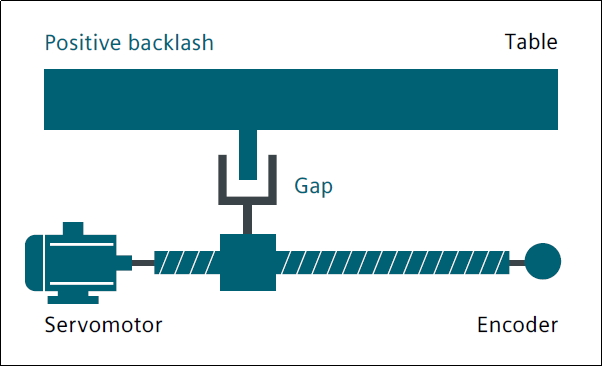

Isinxephezelo sokuhlehla

Ukudluliswa kwamandla okuhamba kancane noma okubambezelekile kwenzeka phakathi kwezingxenye ezihambayo zethuluzi lomshini nezingxenye zalo zokushayela, njengezikulufu zebhola, ngoba ukwakheka komshini okungenazikhala kuzokwandisa kakhulu ukuguga kwethuluzi lomshini, futhi kunzima futhi ukukufeza ngokwemibandela. kwezobuchwepheshe. . Ukudlala ngomshini kuholela ekuphambukeni phakathi kwezindlela ezinyakazayo zezimbazo/ama-spindle kanye namavelu akaliwe wesistimu yokulinganisa engaqondile. Lokhu kusho ukuthi uma umumo usushintshiwe, i-eksisi izohamba kakhulu noma isondele kakhulu, kuye ngosayizi wegebe. Ithebula nezishumeki zalo ezihambisanayo nazo ziyathinteka: uma isishumeki singaphambi kwetafula, sifika endaweni eyaliwe ngaphambili okusho ukuthi umshini empeleni uhamba ibanga elincane. Uma umshini usebenza, ngokusebenzisa umsebenzi wokunxeshezelwa kwe-backlash ku-eksisi ehambisanayo, ukuchezuka okurekhodiwe ngaphambilini kwenziwa kusebenze ngokuzenzakalelayo ngesikhathi sokuhlehla, kudlule ukuchezuka okurekhodiwe ngaphambilini kunani langempela lesikhundla.

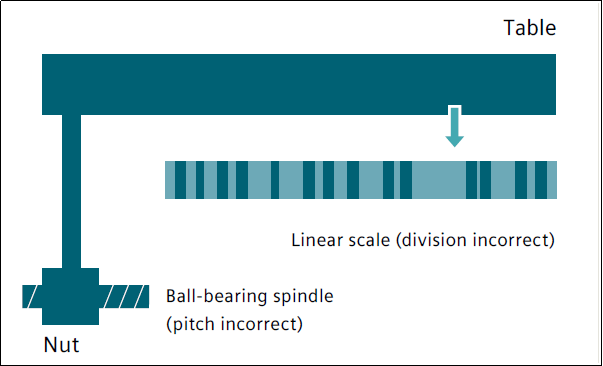

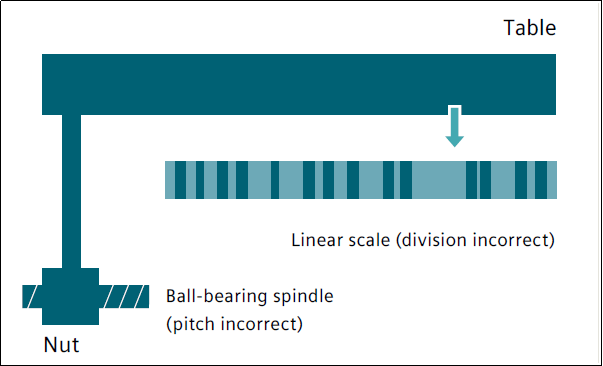

Isinxephezelo sephutha lesikulufu sokuhola

Isimiso sokulinganisa sokulinganisa okungaqondile ohlelweni lokulawula lwe-CNC sisekelwe ekucabangeni ukuthi ukuphakama kwesikulufu sebhola kuhlala kungashintshiwe phakathi kwe-stroke ephumelelayo, ngakho-ke, ngokwembono, indawo yangempela ye-eksisi yomugqa ingathathwa endaweni yolwazi lokunyakaza shayela imoto. Kodwa-ke, amaphutha okukhiqiza kuzikulufu zebhola angabangela ukuchezuka ohlelweni lokulinganisa (okwaziwa nangokuthi amaphutha e-lead screw pitch). Le nkinga ingabhebhethekiswa nakakhulu ngokuchezuka kwesilinganiso (kuye ngesistimu yokulinganisa esetshenzisiwe) kanye namaphutha okufakwa kwesistimu yokulinganisa emshinini (owaziwa nangokuthi amaphutha esistimu yokulinganisa). Ukuze kunxeshezelwe lezi zinhlobo ezimbili zamaphutha, uhlelo lokulinganisa oluzimele (isilinganiso selaser) singasetshenziswa ukukala ijika lephutha lemvelo lethuluzi lomshini we-CNC, bese inani lesinxephezelo elidingekayo ligcinwa ohlelweni lwe-CNC ukuze kunxeshezelwe.

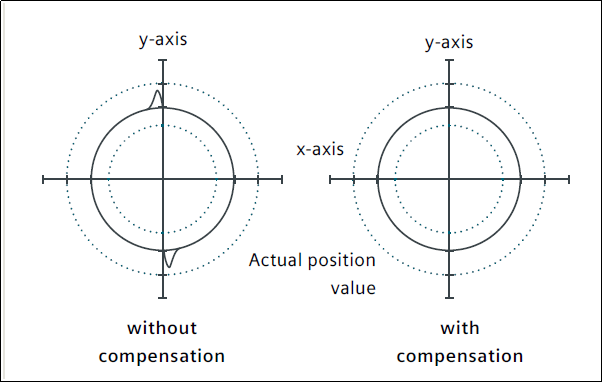

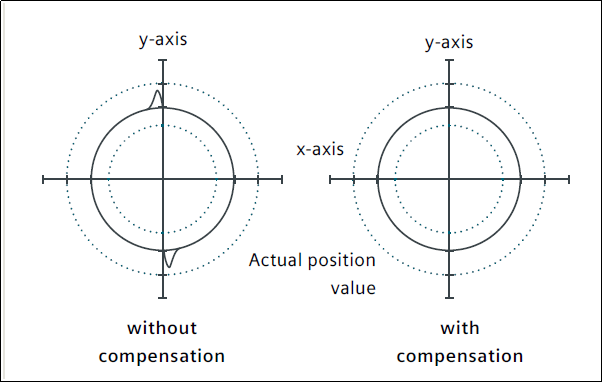

Isinxephezelo sefriction (isinxephezelo sephutha le-quadrant) kanye nesinxephezelo sokungqubuzana okuguquguqukayo

I-Quadrant Error Compensation (ebuye yaziwe ngokuthi I-Friction Compensation) ifaneleka konke okungenhla ukuze kuthuthukiswe kakhulu ukunemba kwekhondiyutha lapho kwenziwa imishini eyindilinga. Isizathu simi kanje: Ekuguqulweni kwe-quadrant, i-eksisi eyodwa ihamba ngezinga eliphezulu lokuphakela kanti enye i-eksisi imile. Ngakho-ke, ukuziphatha okuhlukile kokungqubuzana kwezimbazo ezimbili kungaholela kumaphutha wekhonta. Isinxephezelo sephutha le-quadrant singanciphisa ngempumelelo leli phutha futhi siqinisekise imiphumela emihle kakhulu yokwenza imishini. Ukuminyana kwama-pulses esinxephezelo kungasethwa ngokuya ngejika lesici elincike ekusheshiseni, elinganqunywa futhi libekwe ipharamitha ngokuhlolwa kokuyindilinga. Ngesikhathi sokuhlolwa kokuyindilinga, ukuchezuka phakathi kwendawo yangempela yekhonta eyisiyingi kanye nerediyasi ehleliwe (ikakhulukazi ngesikhathi sokuhamba) kurekhodwa ngobuningi futhi kuboniswe ngesithombe ku-HMI. Enguqulweni entsha yesofthiwe yesistimu, umsebenzi wokunxephezela oshintshashintshayo ohlanganisiwe ungenza isinxephezelo esishintshashintshayo ngokuya ngokuziphatha kokungqubuzana kwethuluzi lomshini ngesivinini esihlukile, kwehlise iphutha langempela lekhontatha yomshini kanye nokuzuza ukunemba kokulawula okuphezulu.

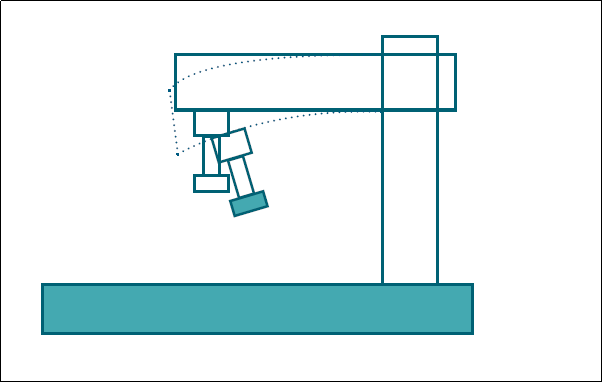

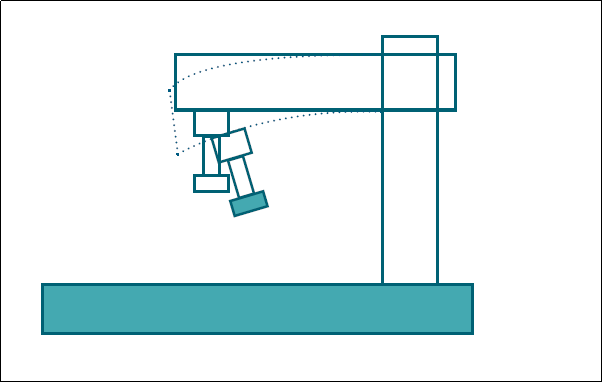

Isinxephezelo Sephutha Le-Sag ne-Engeli

Kudingeka isinxephezelo se-sag uma isisindo sezingxenye zomshini ngamunye sibangela ukuthi izingxenye ezihambayo zinyakaze futhi zitsheke, njengoba kubangela ukuthi izingxenye zomshini ezihlotshaniswayo, okuhlanganisa nesistimu yomhlahlandlela, zintekenteke. Isinxephezelo samaphutha e-angular sisetshenziswa uma izimbazo ezihambayo zingaqondani nezinye nge-engeli elungile (isb. mpo). Njengoba i-offset yendawo enguziro ikhula, kanjalo nephutha lendawo liyakhula. Womabili la maphutha abangelwa isisindo esifile sethuluzi lomshini, noma isisindo sethuluzi nomsebenzi. Amanani esinxephezelo akalwa ngesikhathi sokusebenza abalwa futhi agcinwe ku-SINUMERIK ngokuya ngendawo ehambisanayo ngandlela thize, njengetafula lesinxephezelo. Uma ithuluzi lomshini lisebenza, indawo ye-eksisi efanele ihlanganiswa ngokwenani lesinxephezelo sephoyinti eligciniwe. Ngokunyakaza ngakunye okuqhubekayo, kunezimbazo eziyisisekelo nezinxephezelo. Ukushisa kwesinxephezelo sezinga lokushisa kungabangela izingxenye zomshini ukuthi zande. Ububanzi bokunwetshwa buncike ekushiseni, ekushiseni okushisayo, njll. kwengxenye ngayinye yomshini. Amazinga okushisa ahlukene angabangela ukuma kwangempela kwe-eksisi ngayinye ukuthi kushintshe, okungaba nomthelela omubi ekunembeni komsebenzi owenziwe ngomshini. Lezi zinguquko zenani zangempela zingasuswa isinxephezelo sezinga lokushisa. Amajika ephutha e-eksisi ngayinye kumazinga okushisa ahlukene angachazwa. Ukuze kuhlale kunxeshezelwa ngokunwetshwa kwezinga lokushisa ngendlela efanele, amanani esinxephezelo sezinga lokushisa, indawo yereferensi namapharamitha e-engeli ye-gradient eqondile kufanele adluliselwe kabusha ngokuqhubekayo ukusuka ku-PLC kuya kulawulo lwe-CNC ngamabhulokhi okusebenza. Izinguquko zepharamitha ezingalindelekile ziqedwa ngokuzenzakalelayo isistimu yokulawula ukugwema ukulayisha ngokweqile umshini nokwenza kusebenze imisebenzi yokuqapha.