Amasongo e-piston anezinhlobonhlobo zezinto zokwakha kanye nezakhiwo ezahlukene. Ukukhethwa kwendandatho ye-piston kufanele kucabangele izimo zayo zesevisi, izidingo zokusebenza, uhlobo lwendandatho nezinye izici. Ngokuvamile, indandatho ye-piston yenjini evuthayo yangaphakathi izohlangabezana nalezi zidingo ezilandelayo:

1. Amandla aphezulu ngokwanele emishini ekushiseni okuphezulu

2. Ukumelana nokugqoka kanye ne-coefficient ephansi ye-friction

3. Akulula ukukhiqiza ukunamathela futhi kulula ukugijima kuyo

4. Ukucubungula kulula futhi intengo ishibhile

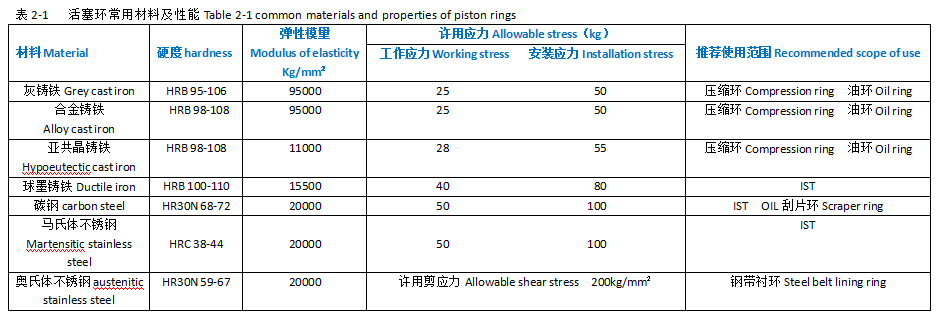

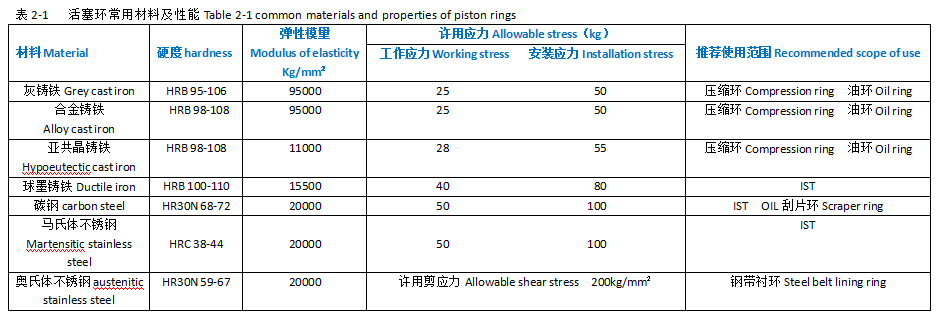

Ngale ndlela, impahla ye-piston ring iyadingeka ukuze ibe namandla athile, ubulukhuni, ukuqina, ukumelana nokugqoka (kuhlanganise nokugcinwa kwamafutha), ukumelana nokugqwala, ukuzinza okushisayo nokucutshungulwa. Njengamanje, indandatho ye-piston ngokuyinhloko iyinsimbi ekhonjiwe. Ngokuqiniswa kwenjini, kunomkhuba wokuguquka kusuka ensimbini empunga iye kwensimbi egayiwe ethambile, insimbi eyinodular nensimbi. Bheka ithebula 2-1 ukuze uthole izinto ezijwayelekile kanye nezakhiwo.

Ithebula 2-1 izinto ezivamile kanye izakhiwo piston izindandatho

Kodwa-ke, isingeniso sanamuhla akuyona indandatho ye-piston yezinto ezivamile, kodwa indandatho ye-ceramic eyinhlanganisela yefilimu ye-ceramic (indandatho ye-ceramic infiltrated piston ring noma indandatho ye-ceramic metal piston okwesikhashana), kamuva ebizwa ngokuthi indandatho ye-ceramic piston.

Amasongo e-Cermet piston enziwa ngokungena kwe-boron nitride (ingxenye ye-cubic boron nitride) izitsha zobumba ezinomsebenzi wokuzigcoba ongqimbeni olungaphezulu lwe-piston ring friction pair at izinga lokushisa eliphansi (ngaphansi kuka-200 ℃) ngokusebenzisa umhwamuko wamakhemikhali we-plasma * othuthukisiwe. Deposition technology", ukuze ungqimba olungaphezulu lokusebenza lwamasongo e-piston lube yi-ceramic. Amasongo e-piston ngemuva kokungeniswa kwe-ceramic anokumelana okuhle kokugqoka, ukumelana nokugqoka kanye nokumelana nokugqwala, Ngakho-ke, impilo yesevisi ye-piston ring ingathuthukiswa. I-ceramic eyinhlanganisela ifakwa ebusweni beringi ye-piston nge-plasma chemical vapor deposition, ehlukile kunqubo yokufafaza nge-ceramic ebusweni bamanye amasongo e-piston. Le ndlela yenqubo ingenza izinto ezihlanganisiwe ze-ceramic zibe namandla okubopha aqinile nobuso bendandatho yepiston ngaphandle kokuqhekeka nokuwa.

Ngaphezu kwalokho, ungqimba oluhlanganisiwe lwe-cermet lunesakhiwo se-elekthronikhi esifana ne-rhodium, ngakho-ke singakwazi ukwenza i-Catalysis Yomlilo enjini futhi sinciphise kakhulu okuqukethwe kokukhishwa kwe-CO ne-HC. Ngakho-ke, izindandatho ze-ceramic ezifakwe nge-piston nazo zinethonya elinamandla.

Ubuchwepheshe be-"Cermet composite film" buphumelele * ukuhlolwa ngo-1997.

Izindandatho ze-ceramic ezifakwe kwi-piston zisetshenziswe kabanzi ezitshalweni ezinkulu zenjini ezinomphumela omuhle wokufaka isicelo.

Yakha "i-ceramics esebenzayo" ehlanganiswe nezinsimbi, enezici ezivelele zobulukhuni obuphezulu, i-coefficient ephansi yokungqubuzana, ukunciphisa ukugqokwa nokuphila isikhathi eside.

Ezingeni lokushisa eliphansi (ngaphansi kuka-200 ℃), i-nitride (into ehlanganisiwe ye-ceramic) ifakwa endaweni yamathuluzi ngokufakwa komhwamuko wamakhemikhali e-plasma.

Izici:

1. Ukukhula kwezinga lokushisa eliphansi. Uma izinga lokushisa lokwakha ifilimu lingaphansi kuka-200 ℃, ngeke kulimaze i-substrate nengaphezulu lesiqephu sokusebenzela, noma kulimaze ucezu lokusebenza, futhi ngeke kuthinte ukunemba komshini nokusebenza komhlangano.

2. Ukuxhumana kuqinile. Ngenxa yokuthi insimbi isakazwa nge-boron nitride kanye ne-cubic boron nitride esimweni se-vacuum plasma ukuze kwakheke ukulahlwa kwezinto ezisebenzayo ze-gradient, amafilimu ayinhlanganisela ngeke axege lapho izinga lokushisa eliphezulu noma umthelela.

3. Kokubili ubulukhuni nokuqina kuyathuthukiswa. Ngenxa yokusatshalaliswa kwezigaba ezimbili kwefilimu eyinhlanganisela nensimbi ukuze kwakheke izinto ezisebenzayo ze-gradient, ayidlali nje indima yokuhlanganiswa okuqinile kongqimba oluguqukayo, kodwa futhi ithuthukisa amandla okubopha, amandla okudonsa kanye nokumelana nokugoba kwe-ceramic, kanye nokuqina kwayo. idlula i-ceramic ngokwayo.

4. Ukumelana okuhle kokugqoka ekushiseni okuphezulu. Imiphumela yokuhlola ibonisa ukuthi uma kuqhathaniswa ne-chromium plating, ukuqina kwefilimu eyinhlanganisela kukhula kakhulu ngokwenyuka kwezinga lokushisa endaweni engu-250 ℃ - 350 ℃, futhi ukuqina kwendawo kukhuphuka ngaphezu kuka-hv210, kuyilapho i-chromium eqinile yehla kakhulu ngemva kwalokho. 250 ℃, futhi yehla cishe ngo-hv110 ngo-350 ℃. Ngakho-ke, uma kuqhathaniswa ne-workpiece ngaphandle kokufakwa kwefilimu eyinhlanganisela, i-ceramic plated workpiece inokumelana kangcono nokugqoka endaweni yokushisa ephezulu.

5. Ukumelana ne-oxidation okunamandla. Imiphumela yokuhlola ibonisa ukuthi ifilimu eyinhlanganisela isenokumelana okuhle ne-oxidation kanye nokumelana ne-acid-base uma izinga lokushisa lingaphezu kuka-1000 ℃.

6. Inomsebenzi we-oxidation kanye ne-catalysis. Lapho i-ceramic ingena endaweni yensimbi, kukhiqizwa inani elifanelekile lesikhala se-electron, okwenza ifilimu eyinhlanganisela ibe nomthelela we-oxidation catalytic ku-CO ne-HC, futhi kunciphisa kakhulu ukungcoliswa komoya wenjini.

7. Ukusebenza okuhle kokusonga nokucwenga. Amafilimu ayinhlanganisela ayi-chemical vapor deposition, ngakho-ke amafilimu ayinhlanganisela angatshalwa noma kuphi lapho igesi ingadlula khona, futhi izimo zokucubungula azinqunyelwe ukuma nokuma kwendawo yokusebenza.

8. Izinkambu ezibanzi zohlelo lokusebenza. Ngaphezu kokusetshenziswa enjinini, ifilimu eyinhlanganisela ibuye ilungele amapheya emishini ehlukahlukene, izinga lokushisa eliphezulu kanye nezingxenye ezimelana nokugqwala, amathuluzi ahlukahlukene okusika kanye nezibungu, futhi ingakwazi ukuzivumelanisa nezinto ezahlukahlukene zensimbi noma ezingezona ezensimbi ngokusebenzisa. ezahlukene inqubo nemingcele.