Zeziphi izinto eziluncedo kuzo zonke iiNjini ze-aluminiyam xa zithelekiswa neeNjini zentsimbi?

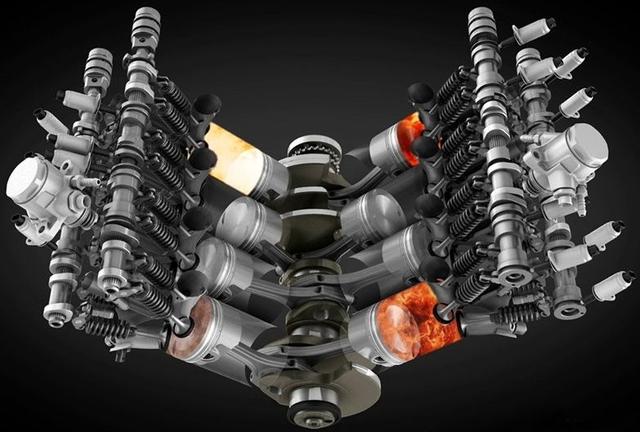

Ibhloko yesilinda ye-injini yepetroli yahlulwe yaba yintsimbi ephosweyo kunye ne-aluminium ephosiweyo. Thelekisa iingenelo kunye nokungalunganga kwe-aluminium cylinder kunye nesilinda yentsimbi:

1) Ubunzima

Ubunzima obuthile be-aluminium buncinci kunobo bentsimbi, kwaye ibhloko ye-aluminium cylinder ilula kakhulu phantsi kwesiseko sokuhlangabezana neemfuno zamandla. I-injini ilula, enefuthe elihle ekusasazeni ubunzima besithuthi, kwaye ubunzima besithuthi bubuye bube lula. Ngoko ke, ngeli xesha, iisilinda ze-aluminium zilawula.

2) Umthamo

Ngesizathu esifanayo, ubunzima obuthile be-aluminiyam buncinci, kwaye amandla okwakhiwa kwe-aluminiyam nganye umthamo weyunithi ungaphantsi kwentsimbi yentsimbi, ngoko ke iisilinda ze-aluminium zihlala zikhulu ngomthamo. I-EA113 / ibhloko ye-cylinder ye-EA888 inomgama ophakathi ukuya kwi-cylinder ye-88mm, ngelixa inguqulo ekhoyo inobubanzi be-cylinder ukuya kwi-82.5mm. Ngaphandle komjelo wamanzi okupholisa, udonga lwesilinda luncinci kakhulu. Ngale ndlela, yonke i-injini ihlangene kakhulu kwaye incinci ngobukhulu. Iisilinda ze-Aluminiyam zinzima ngakumbi ukufezekisa le mpembelelo. Ngeli xesha, ibhloko ye-cylinder ye-cast iron ilawula. [Ukongezwa: Amandla okuqina entsimbi etyhidiweyo inokuba ngaphezulu kwe-1000MPa, ngelixa amandla okuqina e-aviation 7075 aluminiyam ialloy yi-524MPa, ubuninzi bentsimbi yi-7.85, kwaye ubuninzi be-aluminiyam yi-2.7. Ngoko ke, ukuze ufumane amandla afanayo, umthamo we-aluminium alloy kufuneka unyuswe malunga nenye. Amaxesha, kodwa ubunzima bumalunga ne-40% elula]

3) Ukumelana nokubola kunye namandla

I-Aluminiyam kulula ukusabela ngayo ngokwekhemikhali ngamanzi avelisiweyo ngexesha lokutsha, kwaye ukuxhathisa kwayo kokutya akufani noko kufana neebhloko ze-cylinder zentsimbi, ngakumbi kwiinjini ezitshajiweyo ezinobushushu obuphezulu kunye noxinzelelo. Kwaye isiphelo sangaphambili malunga nomthamo, kwelinye icala, xa iimfuno zevolumu ye-injini zincinci ngokwentelekiso, kudla ngokuba nzima ukuphumeza amandla ebloko yesilinda yentsimbi kunye nebhloko ye-aluminium cylinder. Ngoko ke, iinjini ezininzi eziphezulu eziphezulu zisebenzisa iibhloko zetsimbi, ezifana (ngaphambi kwesizukulwana se-9) i-EVO's 286hp 2.0L I4 (4G63), ehlala iphoswe iibhloko zetsimbi. Umda wayo ophezulu wokuguqulwa kwakhona uyaziwa. Ukuba i-cylinder ye-aluminium isetyenzisiweyo, isenokungabi lula. Ngeli xesha, ibhloko ye-cylinder ye-cast iron ilawula.

4) Iindleko

Iindleko ngokwemvelo ukuba i-aluminium cylinder ibiza kakhulu, kwaye akukho nto ichazayo. Ngeli xesha, ibhloko ye-cylinder ye-cast iron ilawula.

I-5) Ukuxhatshazwa kokuqhuma kunye nokutshatyalaliswa kobushushu

I-Aluminiyam iqhuba ubushushu ngokukhawuleza, ngoko inokusebenza kakuhle kokupholisa, okunokunceda injini inciphise amathuba okutsha okungaqhelekanga. Kumlinganiselo ofanayo woxinzelelo, iinjini ze-aluminiyam yesilinda zingasebenzisa i-petroli yomgangatho ophantsi kuneenjini ze-cylinder zentsimbi. Ngeli xesha, ibhloko ye-aluminium cylinder ilawula.

6) I-coefficient ye-friction

Ukuze kuncitshiswe i-inertia yamacandelo abuyiselayo kunye nokwandisa isantya sokujikeleza kunye nesantya sokuphendula, ininzi yeepistons zisebenzisa i-aluminium alloy njengezinto eziphathekayo. Ukuba udonga lwe-cylinder lwenziwe nge-aluminium, i-coefficient of friction phakathi kwe-aluminium kunye ne-aluminium inkulu kakhulu, echaphazela kakhulu ukusebenza kwe-injini. Intsimbi yentsimbi ayinayo ingxaki enjalo. Ngeli xesha, iibhloko ze-iron cylinder zilawula. [Uncediso: ezinye iinjini ezibizwa ngokuba yi "aluminiyam yonke" nazo zisebenzisa iilitha zesilinda zentsimbi]

ukuququmbela:

Izinto eziluncedo ze-aluminium: ubunzima obulula, ukuchithwa kakuhle kobushushu;

Izinto ezilungileyo zentsimbi: zitshiphu kwaye zihlala ixesha elide.