Impeta ya piston ifite ibikoresho byinshi bitandukanye nibintu bitandukanye. Guhitamo ibikoresho bya piston bigomba gusuzuma imiterere ya serivisi, ibisabwa mu mikorere, ubwoko bwimpeta nibindi bintu. Muri rusange, ibikoresho bya piston ya moteri yo gutwika imbere bigomba kuba byujuje ibi bikurikira:

1. Imbaraga zihagije zihagije mubushyuhe bwinshi

2. Kwambara kwihanganira hamwe na coefficient de friction yo hasi

3. Ntibyoroshye kubyara adhesion kandi byoroshye gukora

4. Gutunganya biroroshye kandi igiciro kirahendutse

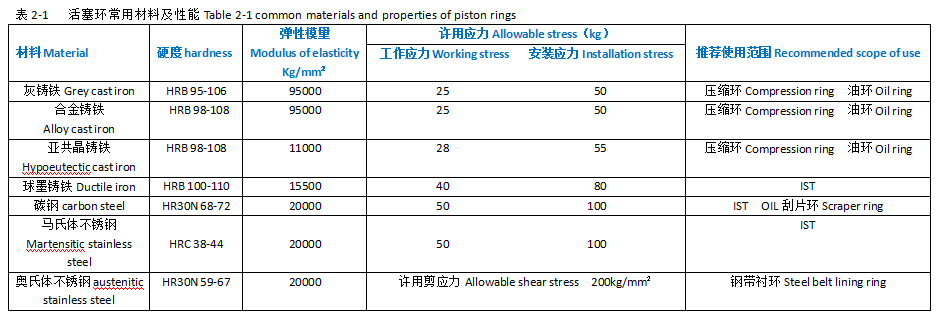

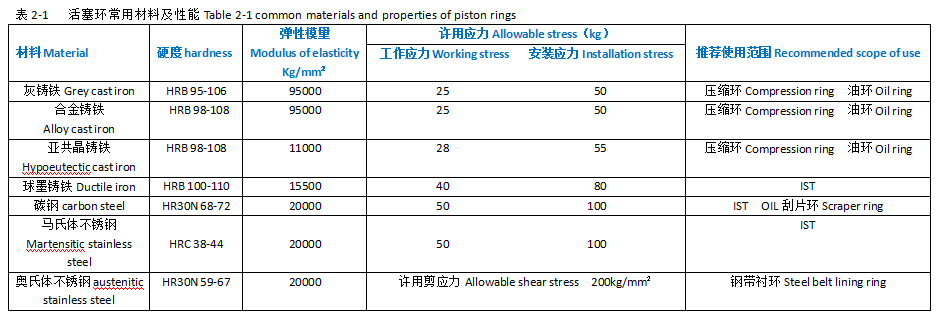

Muri ubu buryo, ibikoresho bya piston bisabwa kugira imbaraga runaka, gukomera, gukomera, kwambara birwanya (harimo kubika amavuta), kurwanya ruswa, guhagarika ubushyuhe no gutunganya. Kugeza ubu, ibikoresho by'impeta ya piston bikozwe cyane cyane. Hamwe nogukomeza moteri, hariho inzira yo kuva mubyuma byumuhondo ujya mubyuma byoroshye, ibyuma bya nodular byuma nicyuma. Reba imbonerahamwe 2-1 kubikoresho bisanzwe hamwe nibintu.

Imbonerahamwe 2-1 ibikoresho bisanzwe nibiranga impeta ya piston

Nyamara, intangiriro yuyu munsi ntabwo impeta ya piston yibikoresho bisanzwe, ahubwo ni icyuma ceramic compte ya firime piston impeta (ceramic infiltrated ring piston ring ceramic metal piston ring for short), nyuma yiswe icyuma cyitwa ceramic piston impeta.

Impeta ya piston ya Cermet ikorwa no kwinjira muri nitride ya boron (igice cya nitride ya cubic boron) hamwe na * kwikorera amavuta mu gice cyo hejuru cy’imisemburo ya piston impuzandengo ku bushyuhe buke (munsi ya 200 ℃) ukoresheje imyuka y’imyuka ya plasma yo mu isi * yateye imbere. tekinoroji yo kubitsa ", kugirango ubuso bukora hejuru yimpeta ya piston ni ceramic. Impeta ya piston nyuma yo kwinjira muri ceramic ifite imbaraga zo kurwanya kwambara, kurwanya kwambara no kurwanya ruswa, Kubwibyo, ubuzima bwumurimo wimpeta ya piston burashobora kunozwa. Ceramic yibumbiye hamwe yinjiye hejuru yimpeta ya piston ikoresheje imyuka ya plasma ya chimique, ikaba itandukanye nuburyo bwo gutera ceramic kumera hejuru yizindi mpeta za piston. Ubu buryo bwo gutunganya bushobora gutuma ibikoresho bya ceramic bigize ibintu bigira imbaraga zihuza hamwe nubuso bwimpeta ya piston itavunitse kandi igwa.

Byongeye kandi, cermet igizwe na cermet igizwe nuburyo bwa elegitoronike busa na rodium, bityo irashobora gukora Catalizike ya Combustion muri moteri kandi ikagabanya cyane ibyuka bihumanya CO na HC. Kubwibyo, ceramic yatewe impeta ya piston nayo igira ingaruka za catalitiki.

Ikoranabuhanga rya "Cermet composite film" ryatsinze * isuzuma mu 1997.

Ceramic yatewe impeta ya piston yakoreshejwe cyane muruganda rukora moteri ningaruka nziza yo gukoresha.

Ikora "ceramics ikora" yongewemo nibyuma, bifite ibimenyetso byingenzi biranga ubukana bwo hejuru, coefficient de fraisse nkeya, kugabanya kwambara no kuramba.

Ku bushyuhe buke (munsi ya 200 ℃), nitride (compte ceramic material) yinjiye mubikoresho byifashishwa na plasma chimique imyuka.

Ibiranga:

1. Gukura ubushyuhe buke. Iyo ubushyuhe bwo gukora firime buri munsi ya 200 ℃, ntabwo byangiza substrate nubuso bwibikorwa, cyangwa ngo bihindure igihangano, kandi ntibizagira ingaruka kubikorwa byo gutunganya no gukora.

2. Ihuza rirakomeye. Kubera ko icyuma gitandukana na nitride ya boron na nitride ya cubic boron muri leta ya vacuum kugirango ibe guta ibikoresho bikora buhoro buhoro, firime ikomatanya ntishobora gukuramo ubushyuhe bwinshi cyangwa ingaruka.

3. Gukomera no gukomera byombi biratera imbere. Bitewe no gukwirakwiza ibyiciro bibiri bya firime hamwe nicyuma kugirango bikore ibintu bigenda byoroha, ntabwo bigira uruhare runini rwo guhuza ibice byinzibacyuho, ahubwo binateza imbere imbaraga zihuza, ubushobozi bwimbaraga hamwe no kunama kwa ceramic, hamwe nubukomezi bwayo irenze iya ceramic ubwayo.

4. Kurwanya kwambara neza mubushyuhe bwinshi. Ibisubizo byubushakashatsi byerekana ko ugereranije no gufata chromium, ubukana bwa firime yibintu byiyongera cyane hamwe no kwiyongera kwubushyuhe mubidukikije bwa 250 ℃ - 350 and, kandi ubukana bwubuso bwiyongera kurenza hv210, mugihe chromium ikomeye igabanuka cyane nyuma ya 250 ℃, kandi igabanuka nka hv110 kuri 350 ℃. Kubwibyo, ugereranije nakazi kakozwe nta plaque ikomatanyirijwe hamwe, ceramic plaque yamashanyarazi ifite imyambarire myiza yo guhangana nubushyuhe bwo hejuru.

5. Kurwanya okiside ikomeye. Ibisubizo byubushakashatsi byerekana ko firime ikomatanya igifite imbaraga zo kurwanya okiside hamwe na aside irwanya aside iyo ubushyuhe burenze 1000 ℃.

6. Ifite imikorere ya okiside na catalizike. Iyo ceramic yinjiye hejuru yicyuma, hakorwa umwanya ukwiye wa elegitoronike, bigatuma firime ikomatanya igira ingaruka za okiside ya catisitiya kuri CO na HC, kandi bikagabanya cyane umwanda uhumanya ikirere cya moteri.

7. Gukora neza no gufata neza. Filime ikomatanya ni imyuka ya chimique, bityo firime ikomatanya irashobora guhingwa ahantu hose gaze ishobora kunyura, kandi uburyo bwo gutunganya ntibugarukira kumiterere numwanya wakazi.

8. Imirima yagutse yo gusaba. Usibye gukoreshwa kuri moteri, firime ikomatanya kandi irakwiriye kubice bibiri byo guteranya imashini zitandukanye, ubushyuhe bwo hejuru hamwe n’ibice birwanya ruswa, ibikoresho bitandukanye byo gutema hamwe nububiko, kandi birashobora guhuza ibyuma bitandukanye cyangwa ibikoresho bitari ibyuma binyuze ibipimo bitandukanye.