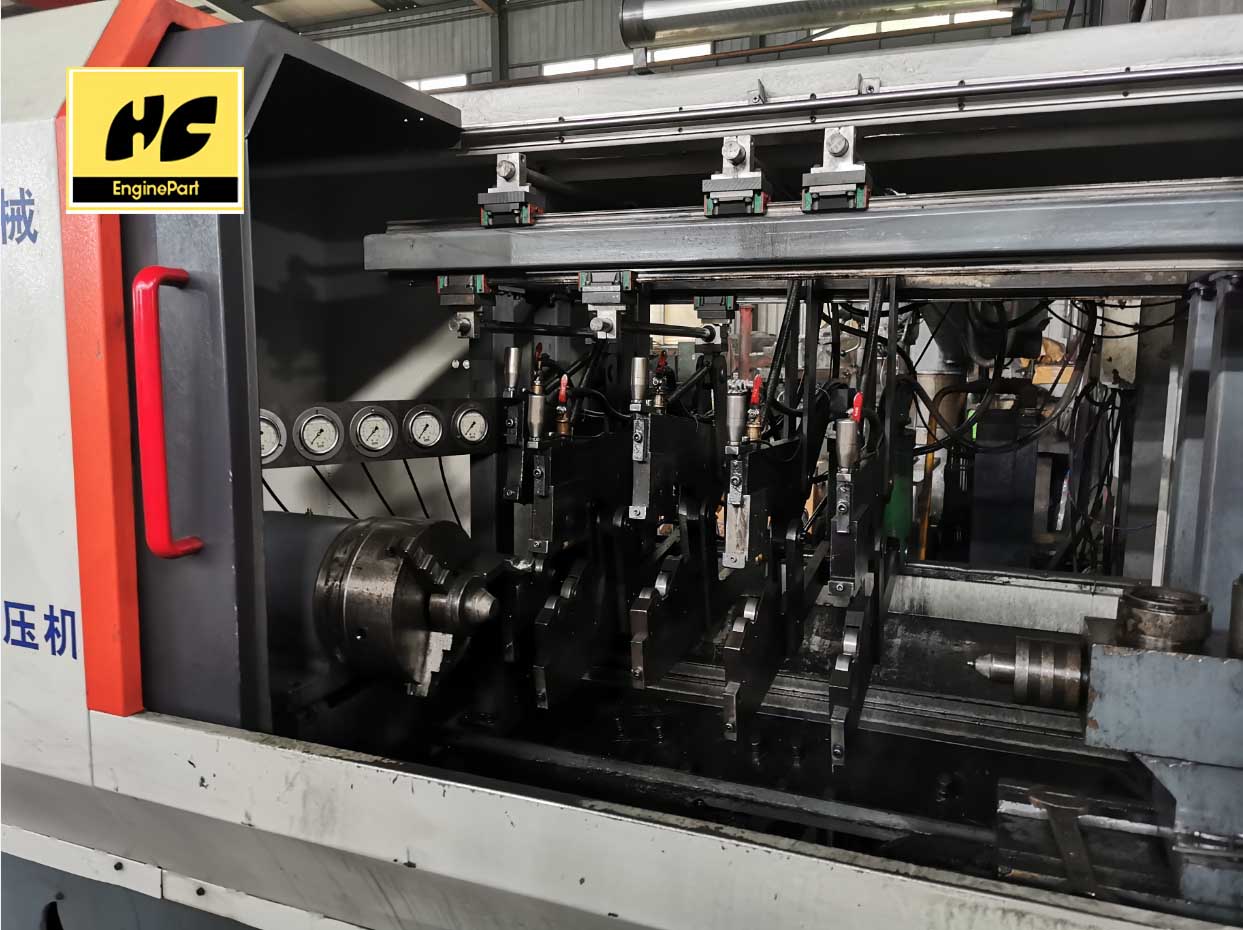

Crankshaft Fillet Rolling Machine

2021-02-20

Regarding the HEGENSCHEIDT MFD7895 crankshaft rolling machine, its control system uses Siemens PLC S7-300. The machine tool is equipped with 9 rolling units. These units are used to roll and straighten the crankshaft. The maximum rolling pressure is 30kN; pulse type Rolling the connecting rod neck reduces the deformation of the workpiece; through the pressure sensor, position sensor and rolling depth sensor integrated in the rolling unit, the detection and monitoring of the rolling pressure is realized; after rolling, the main journal beating is automatically detected and passed the rolling Straightening; equipped with broken tool detection device; electronic measuring probe to measure the radial runout of all main journals of crankshaft; detecting the highest point of connecting rod neck through the laser head to identify the types of parts.