Mgbanaka piston nwere ihe dị iche iche dị iche iche na ihe dị iche iche. Nhọrọ nke ihe mgbanaka piston kwesịrị ịtụle ọnọdụ ọrụ ya, ihe ndị chọrọ ịrụ ọrụ, ụdị mgbanaka na ihe ndị ọzọ. N'ikwu okwu n'ozuzu, ihe mgbanaka piston nke injin combustion n'ime ga-emezu ihe ndị a:

1. High ezu n'ibu ike na elu okpomọkụ

2. Yiri nguzogide na ọnụ ọgụgụ esemokwu dị ala

3. Ọ dịghị mfe ịmepụta adhesion na mfe ịgba ọsọ

4. Nhazi ahụ dị mma na ọnụahịa dị ọnụ ala

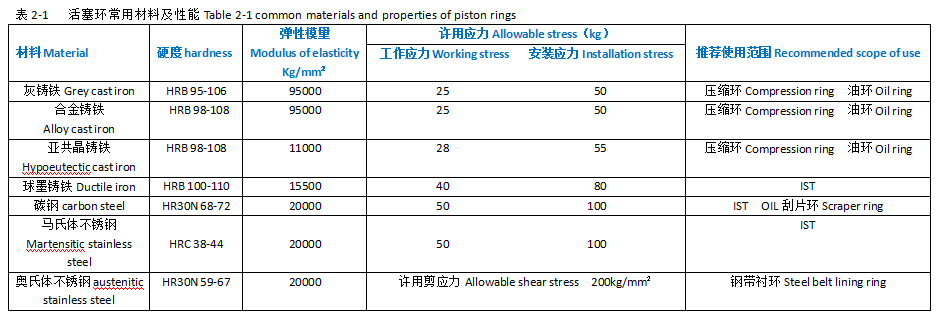

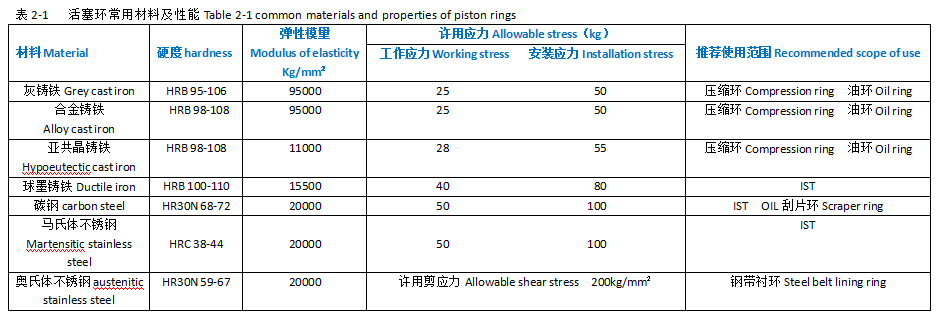

N'ụzọ dị otú a, a na-achọrọ ihe mgbanaka piston ka ọ nwee ike ụfọdụ, ike siri ike, ngbanwe, na-eguzogide ọgwụ (gụnyere nchekwa mmanụ), nguzogide corrosion, nkwụsi ike ọkụ na nhazi. Ka ọ dị ugbu a, ihe mgbanaka piston na-abụkarị nke a na-akpụ akpụ. Site n'ịdị ike nke injin, a na-enwe usoro mgbanwe site na nkedo isi awọ gaa na nkedo nke nwere ike ihie, igwe nkedo nodular na ígwè. Hụ tebụl 2-1 maka akụrụngwa na akụrụngwa nkịtị.

Tebụl 2-1 ihe ndị a na-ahụkarị na ihe ndị yiri mgbaaka piston

Otú ọ dị, okwu mmeghe nke taa abụghị mgbanaka piston nke ihe ndị a na-ahụkarị, ma metal seramic composite film piston ring (seramiiki infiltrated piston ring or ceramic metal piston ring for short), nke a na-ezo aka na ya dị ka mgbanaka seramiiki ígwè.

A na-eme mgbanaka piston cermet site na ịbanye boron nitride (akụkụ nke cubic boron nitride) ceramics nwere * ọrụ mmanye onwe ya n'ime oyi akwa nke piston mgbanaka esemokwu na obere okpomọkụ (n'okpuru 200 ℃) site na iji ụwa * dị elu "plasma vapor" teknụzụ nkwụnye ego", nke mere na oyi akwa na-arụ ọrụ nke mgbanaka piston bụ seramiiki. Mgbanaka piston mgbe infiltration seramiiki na-enwe ezigbo nguzogide na-eyi, na-eyi nguzogide na corrosion eguzogide, Ya mere, ndụ ọrụ nke piston mgbanaka nwere ike imeziwanye. A na-abanye seramiiki mejupụtara n'elu mgbanaka piston site na ntinye mmiri kemịkalụ plasma, nke dị iche na usoro ịgbasa seramiiki n'elu mgbanaka piston ndị ọzọ. Usoro usoro a nwere ike ime ka seramiiki ihe mejupụtara nwere ike jikọta ya na elu nke mgbanaka piston na-enweghị mgbawa ma daa.

Na mgbakwunye, cermet composite oyi akwa nwere ihe eletrọnịkị ihe owuwu yiri rhodium, n'ihi ya, ọ nwere ike na-ebu Combustion Catalysis na engine na-ebelata ntọhapụ nke CO na HC nke ukwuu. Ya mere, seramiiki impregnated piston yiri mgbaaka nwekwara mmetụta catalytic.

Teknụzụ "Cermet composite film" gafere nyocha * na 1997.

A na-eji mgbanaka piston seramiiki eme ihe n'ọtụtụ ebe na nnukwu ụlọ ọrụ injin nwere mmetụta ngwa dị mma.

Ọ na-etolite "seramiki na-arụ ọrụ" jikọtara ya na ọla, nke nwere njirimara pụtara ìhè nke ịdị elu elu elu, ọnụ ọgụgụ esemokwu dị ala, mbelata iyi na ogologo ndụ ọrụ.

Na obere okpomọkụ (n'okpuru 200 ℃), nitride (ihe mejupụtara seramiiki mejupụtara) na-abanye n'elu ngwá ọrụ site na ntinye vapor plasma.

Atụmatụ:

1. Obere okpomọkụ uto. Mgbe ihe nkiri na-akpụ okpomọkụ dị n'okpuru 200 ℃, ọ gaghị emebi mkpụrụ na elu nke workpiece, ma ọ bụ deform workpiece, na ọ gaghị emetụta machining ziri ezi na mgbakọ arụmọrụ.

2. Njikọ ahụ siri ike. N'ihi na ígwè ahụ na-agbasa na boron nitride na cubic boron nitride n'ọnọdụ plasma na-adịghị ahụkebe iji mepụta ihe ndị na-arụ ọrụ gradient na-arụ ọrụ, ihe nkiri ndị mejupụtara agaghị apụpụ na oke okpomọkụ ma ọ bụ mmetụta.

3. Ma isi ike na ike na-emeziwanye. N'ihi na abụọ-adọ mgbasa nke ihe mejupụtara ihe nkiri na metal na-etolite mmasị gradient ọtọ ihe onwunwe, ọ bụghị nanị na-arụ ọrụ nke ike Nchikota Transition oyi akwa, ma na-mma na bonding ike, tensile ikike na ekwe iguzogide seramiiki, na ya siri ike. karịa nke seramiiki n'onwe ya.

4. Nguzogide dị mma na oke okpomọkụ. Nsonaazụ nnwale na-egosi na ma e jiri ya tụnyere chromium plating, ike nke ihe nkiri ahụ mejupụtara na-abawanye nke ukwuu site na mmụba nke okpomọkụ na gburugburu 250 ℃ - 350 ℃, na ike elu na-abawanye karịa hv210, ebe chromium siri ike na-ebelata nke ukwuu mgbe ọ gasịrị. 250 ℃, ma na-ebelata ihe dịka hv110 na 350 ℃. Ya mere, tụnyere workpiece na-enweghị mejupụtara film plating, na seramiiki plated workpiece nwere mma eyi iguzogide na elu okpomọkụ gburugburu ebe obibi.

5. Mgbochi oxidation siri ike. Nsonaazụ nnwale na-egosi na ihe nkiri ahụ mejupụtara ka nwere ezigbo nguzogide oxidation na nguzogide acid-base mgbe okpomọkụ karịrị 1000 ℃.

6. Ọ nwere ọrụ nke oxidation na catalysis. Mgbe seramiiki na-abanye n'ime elu igwe, a na-emepụta oghere electron kwesịrị ekwesị, nke na-eme ka ihe nkiri ahụ mejupụtara nwere mmetụta oxidation catalytic na CO na HC, ma na-ebelata oke mmetọ ikuku nke engine.

7. Ezi winding na plating arụmọrụ. Ihe nkiri ndị mejupụtara bụ ntinye mmiri nke kemịkalụ, ya mere enwere ike ịkụ ihe nkiri ihe nkiri n'ebe ọ bụla gas nwere ike ịgafe, na ọnọdụ nhazi adịghị ejedebe site na ọdịdị na ọnọdụ nke workpiece.

8. Obosara ngwa ngwa. Na mgbakwunye na itinye ya na injin ahụ, ihe nkiri ahụ mejupụtara ihe nkiri ahụ dịkwa mma maka ụzọ abụọ esemokwu nke igwe dị iche iche, akụkụ dị elu na-eguzogide corrosion, ngwaọrụ ịkpụ dị iche iche na ịkpụzi, ma nwee ike imeghari na ihe dị iche iche metal ma ọ bụ ihe na-abụghị ọla. dị iche iche usoro parameters.