Embonini yokukhiqiza, abanye abantu bake balinganisela ukuthi izinto zokusebenza eziyindilinga zivame kakhulu kunezicucu zokusebenza eziyisicaba, kusukela kuzikulufu, amantongomane, ama-gaskets, amasilinda nama-bearings. Ukusetshenziswa kwama-workpieces ayindilinga kuphezulu kakhulu.

Kulezi zingxenye ezijikelezayo, inkinga ephuthuma kakhulu okufanele ixazululwe yindlela yokuhlola isimo sazo esiyindilinga sangempela. Namuhla, sizokwethula izimpawu nezincazelo ezihlobene nokujikeleza (amazinga ayisithenjwa: ISO/DIS 1101:2017, ISO 5459)

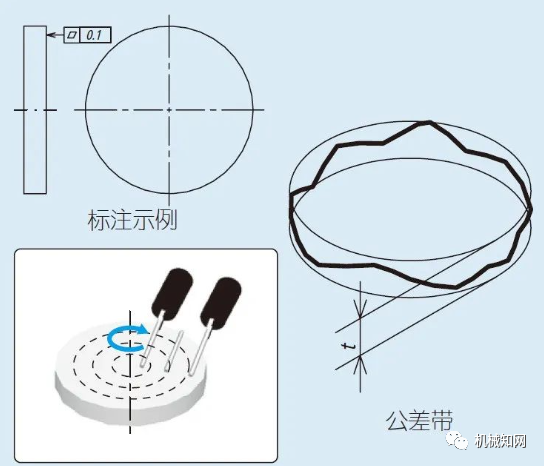

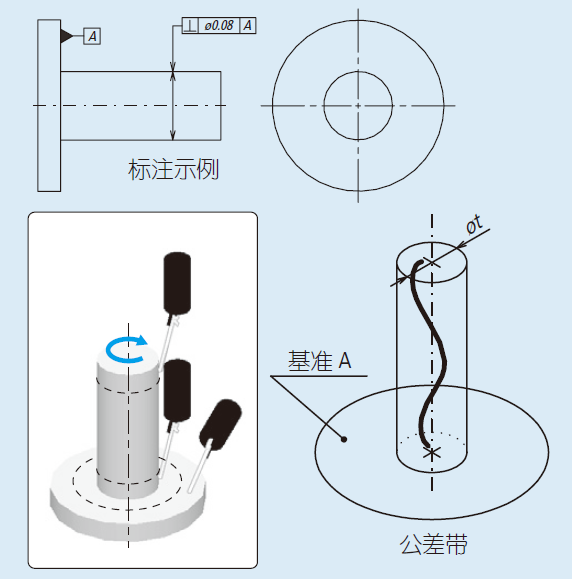

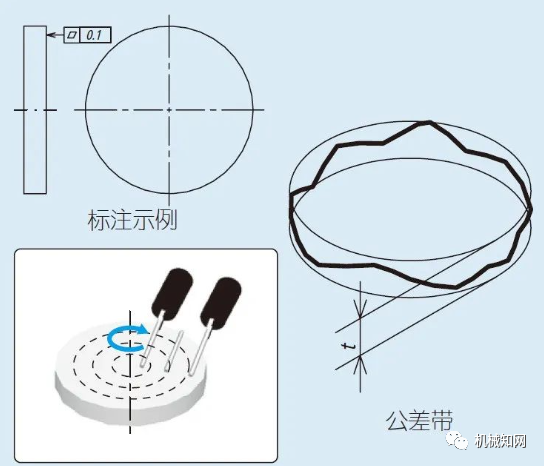

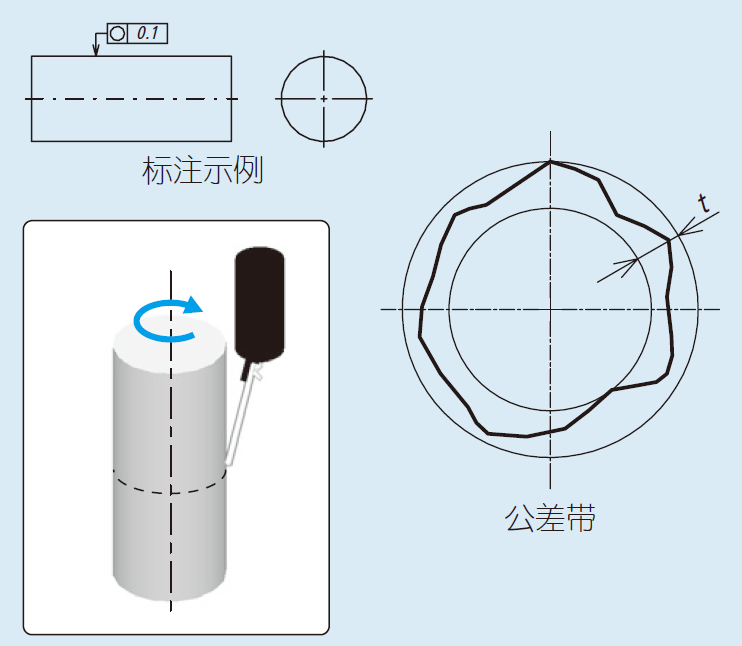

Ukujikeleza

Ukukhishwa kwesiyingi kufanele kukhawulelwe endaweni yokubekezelelana phakathi kwemibuthano egxilile ye-coplanar enomehluko werediyasi ka-t.

.jpg)

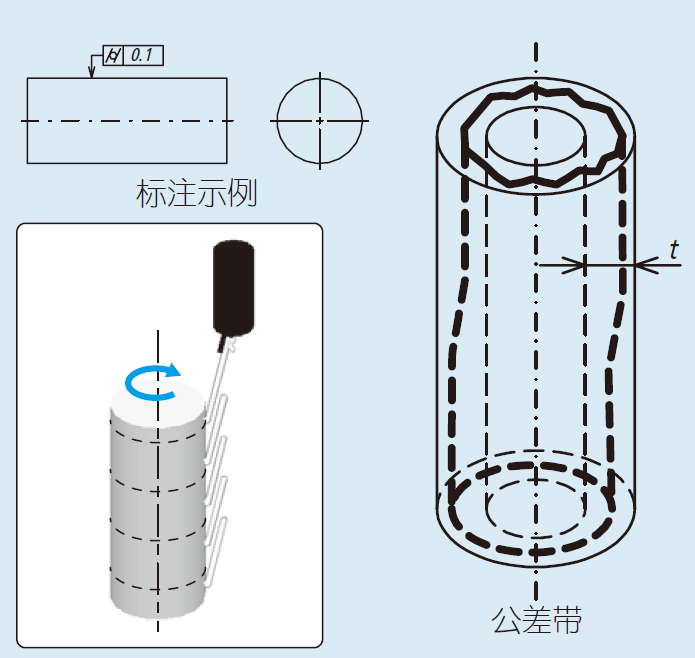

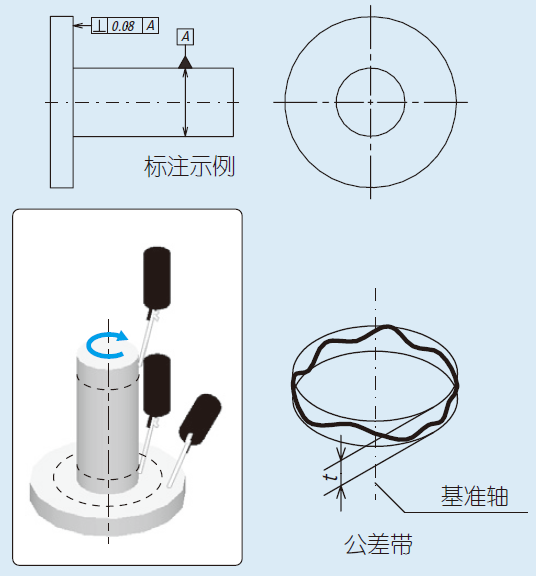

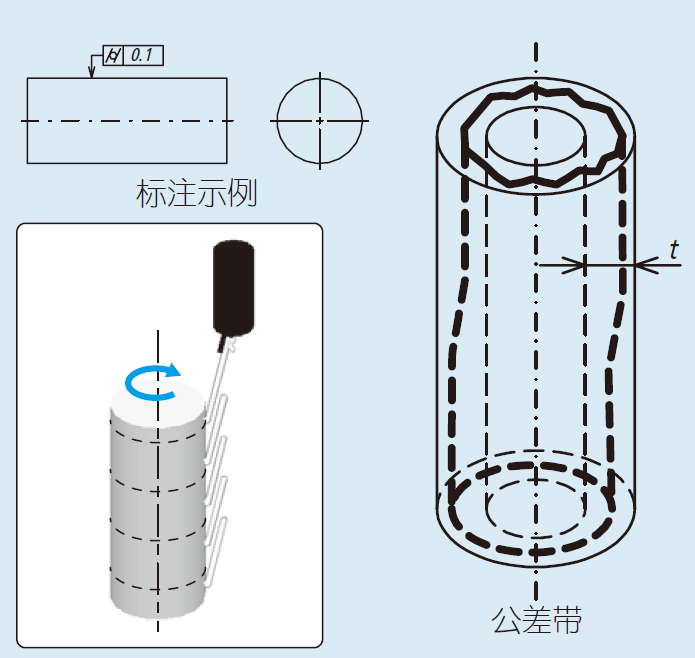

Ukuqondile

Imiphetho ekhishwe endaweni eyi-cylindrical kufanele ikhawulelwe endaweni yokubekezelela phakathi kwemigqa emibili ehambisanayo enebanga lika-t endaweni ecacisiwe.

Ukucaba

Yindawo ephakathi kwezindiza ezimbili ezifanayo ezinebanga lenani lokubekezelela t.

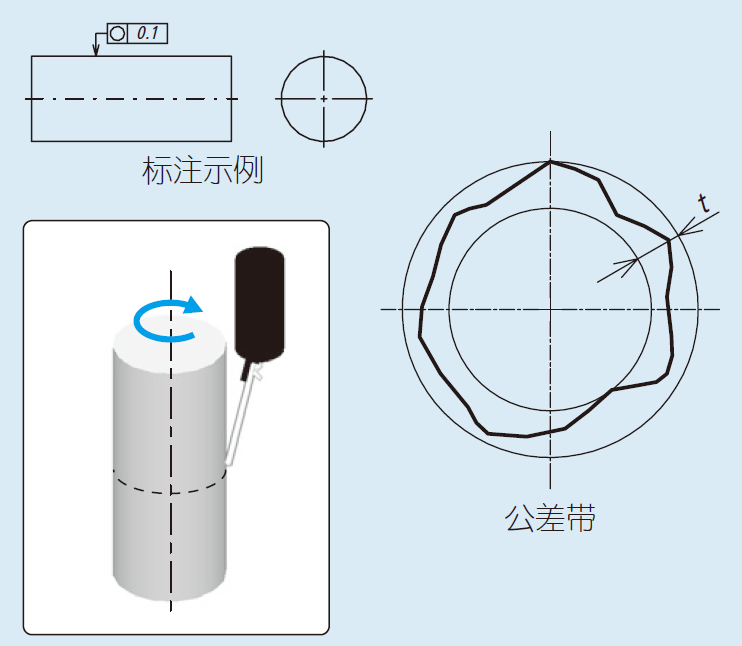

I-Cylindricity

Ukukhishwa kwezindawo eziyi-cylindrical kufanele kukhawulelwe endaweni yokubekezelelana eyakhiwe phakathi kwezindawo ezimbili eziyi-coaxial cylindrical ezinomehluko we-radius we-t.

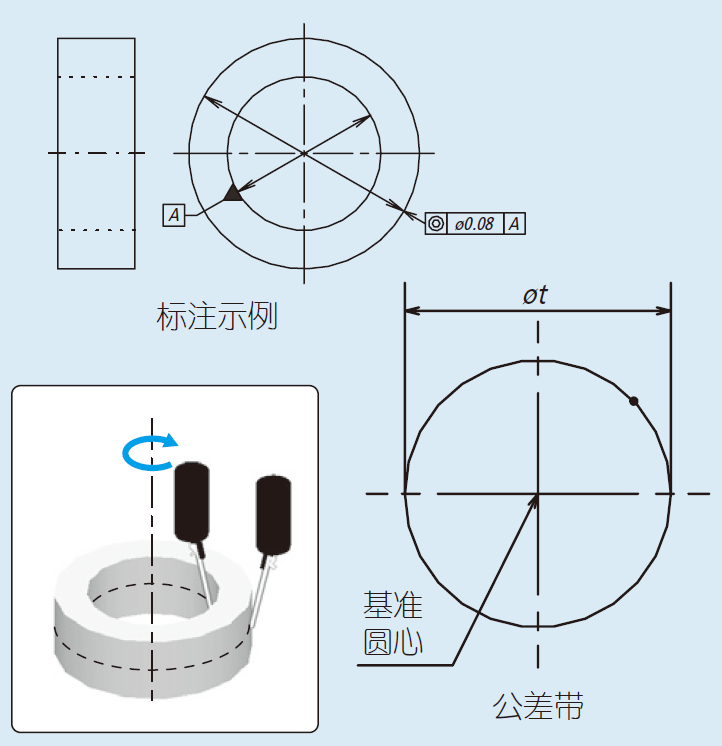

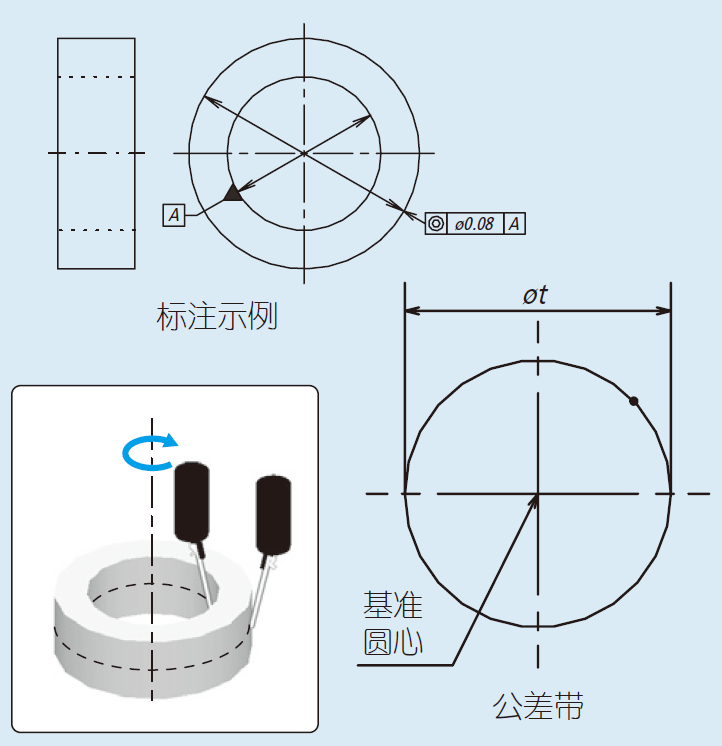

I-Concentricity

Isikhungo sokukhipha umbuthano kufanele sikhawulelwe ngaphakathi kwendawo yokubekezelelana eyakhiwe yindilinga enobubanzi buka-t obugxile nereferensi.

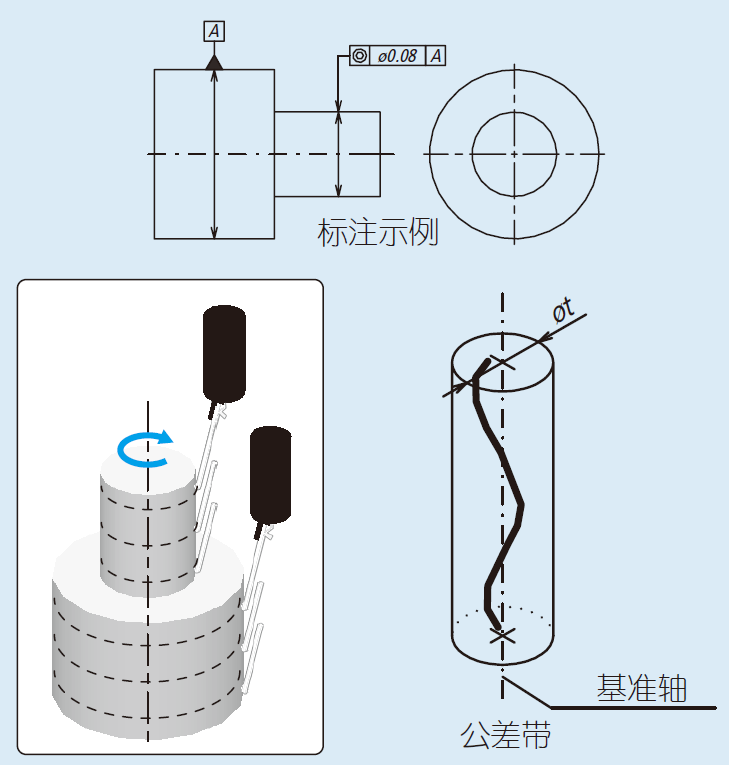

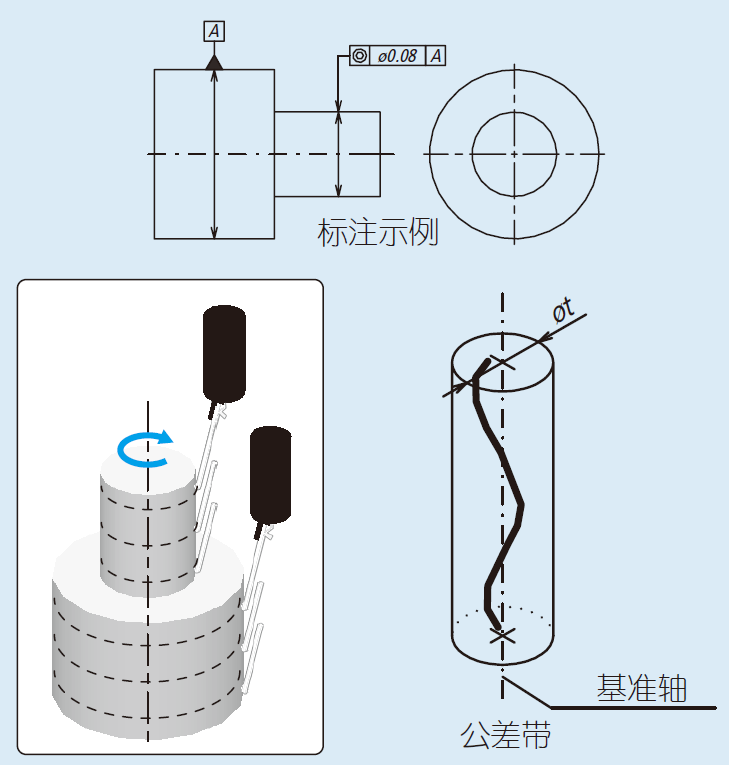

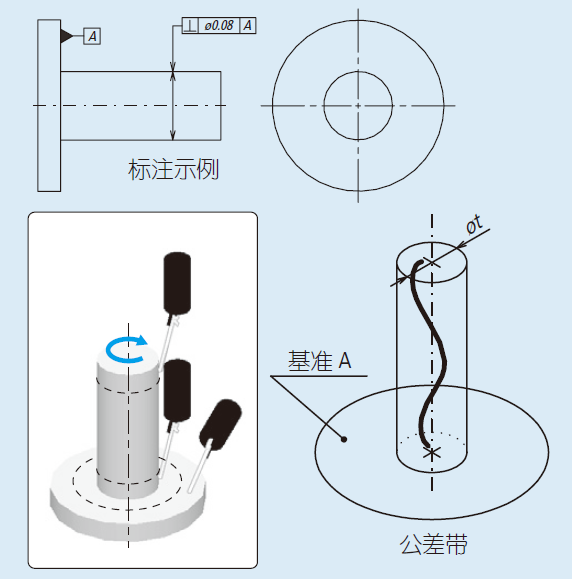

I-coaxiality

I-eksisi ekhishiwe kufanele ikhawulelwe ngaphakathi kwendawo yokubekezelelana eyakhiwe indawo eyisilinda enobubanzi buka-t obuyi-coaxial nereferensi.

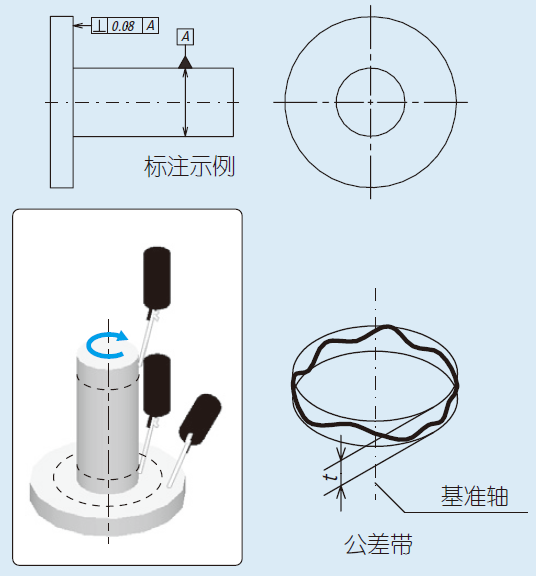

ukuma

I-eksisi ekhishiwe kufanele ikhawulelwe endaweni yokubekezelela eyakhiwe indawo eyi-cylindrical enobubanzi buka-t futhi i-perpendicular endizeni yereferensi.

.jpg)