Ukutenxa okunxulumene noomatshini okucwangcisiweyo kwezixhobo zoomatshini kunokurekhodwa ngokucwangcisiweyo, kodwa ukutenxa kusengavela okanye kwande ngexesha lokusetyenziswa okulandelayo ngenxa yemeko yokusingqongileyo efana nobushushu okanye umthwalo womatshini. Kule meko, i-SINUMERIK inokubonelela ngemisebenzi eyahlukeneyo yembuyekezo. Buyekeza ukutenxa usebenzisa imilinganiselo esuka kwizikhowuli zendawo (umz. igratings) okanye izivamvo ezongezelelweyo (umz. i-laser interferometers, njl.njl.) ukuze ufumane iziphumo ezingcono zomatshini. Kulo mbandela, siya kwazisa imisebenzi yembuyekezo eqhelekileyo ye-SINUMERIK. Imijikelezo yokulinganisa ye-SINUMERIK esebenzayo efana ne-"CYCLE996 Motion Measurement" inokubonelela ngenkxaso ebanzi kubasebenzisi bokugqibela ngexesha lokubeka iliso ngokuqhubekayo kunye nokugcinwa kwezixhobo zoomatshini.

Imbuyekezo yasemva

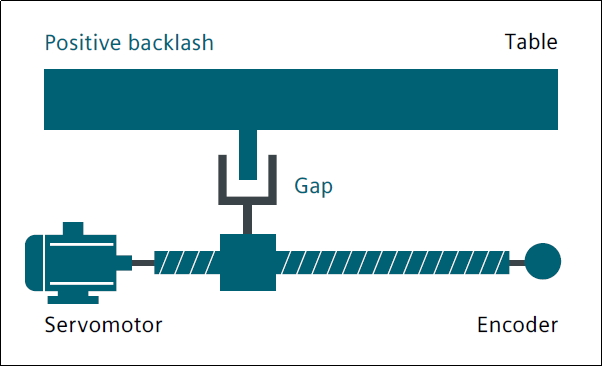

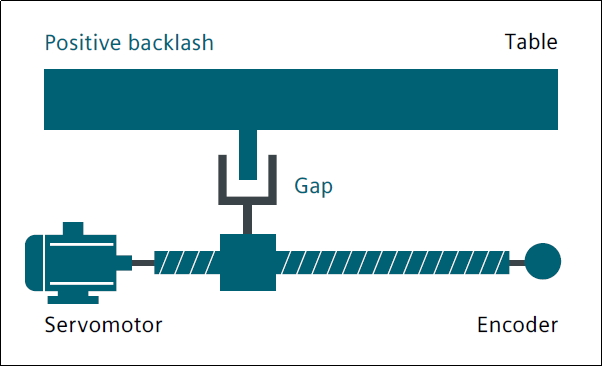

Ukuhanjiswa kwamandla okwethutyana okanye okulibazisekayo kwenzeka phakathi kweendawo ezihambayo zesixhobo somatshini kunye neenxalenye zayo zokuqhuba, njengezikrufu zebhola, kuba isakhiwo somatshini esingenazikhewu siya kwandisa kakhulu ukunxiba kwesixhobo somatshini, kwaye kunzima ukufezekisa ngokwemiqathango. yeteknoloji. . Ukudlala koomatshini kukhokelela ekuphambukeni phakathi kweendlela ezihambayo ze-axes / izikhonkwane kunye namaxabiso alinganisiweyo enkqubo yokulinganisa engathanga ngqo. Oku kuthetha ukuba xa i-orientation itshintshiwe, i-axis iya kuhamba kakhulu okanye isondele kakhulu, kuxhomekeke kubukhulu besithuba. Itheyibhile kunye neekhowudi zayo ezihambelanayo nazo ziyachaphazeleka: ukuba i-encoder iphambi kwetafile, ifikelela kwindawo eyalelweyo ngaphambili okuthetha ukuba umatshini ngenene uhamba umgama omncinci. Xa umatshini usebenza, ngokusebenzisa umsebenzi wembuyekezo ye-backlash kwi-axis ehambelanayo, ukuphambuka okurekhodiweyo kwangaphambili kusebenze ngokuzenzekelayo ngexesha lokuguqulwa, ukuphakamisa ukuphambuka okurekhodiweyo kwangaphambili kwixabiso lendawo yangempela.

Lead screw pitch pitch imbuyekezo

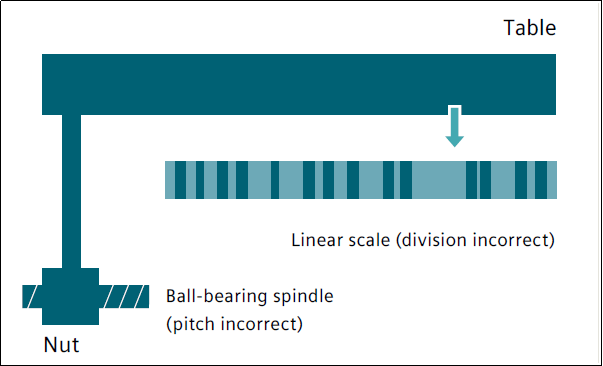

Umgaqo wokulinganisa wokulinganisa ngokungathanga ngqo kwinkqubo yokulawula ye-CNC isekelwe kwingcinga yokuba i-pitch ye-screw yebhola ihlala ingatshintshi ngaphakathi kwe-stroke esebenzayo, ngoko ke ithiyori, indawo yokwenyani ye-axis yomgca inokufunyanwa kwindawo yolwazi lwentshukumo ye qhuba injini. Nangona kunjalo, iimpazamo zokuvelisa kwizikrufu zebhola zinokubangela ukutenxa kwindlela yokulinganisa (ekwaziwa ngokuba ziimpazamo ze-lead screw pitch). Le ngxaki inokugqithwa ngakumbi ngokunxaxha komlinganiselo (kuxhomekeke kwindlela yokulinganisa esetyenziswayo) kunye neempazamo zofakelo lwenkqubo yokulinganisa kumatshini (owaziwa ngokuba ziimpazamo zenkqubo yokulinganisa). Ukuze kuhlawulwe ezi ntlobo zimbini zeempazamo, inkqubo yokulinganisa ezimeleyo (i-laser measurement) ingasetyenziselwa ukulinganisa igophe lemposiso yendalo yesixhobo somatshini we-CNC, kwaye ke ixabiso lembuyekezo elifunekayo ligcinwa kwinkqubo ye-CNC yembuyekezo.

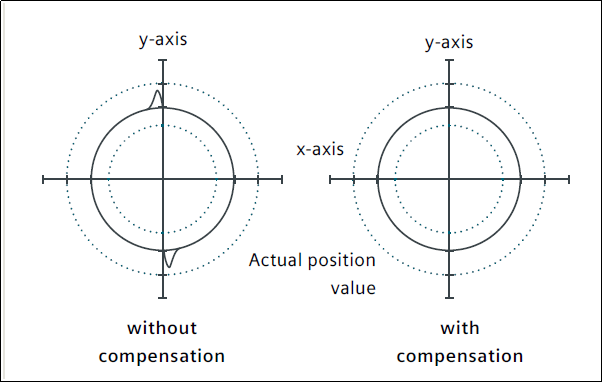

Imbuyekezo yefriction (imbuyekezo yempazamo yequadrant) kunye nembuyekezo yefriction eguqukayo

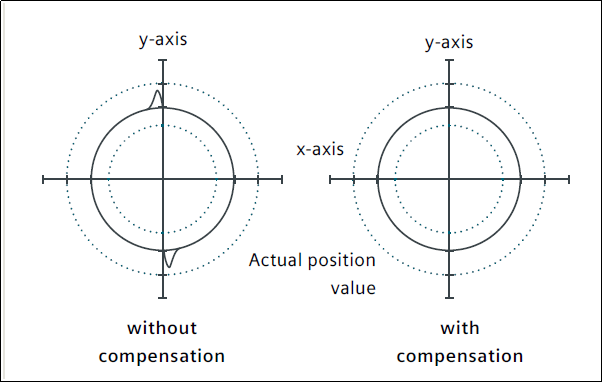

Imbuyekezo yempazamo yeQuadrant (ekwabizwa ngokuba yiFriction Compensation) ilungele konke oku kungentla ukuze kuphuculwe kakhulu ukuchaneka kwecontour xa kusenziwa iicontours ezijikelezayo. Isizathu sesi ngolu hlobo lulandelayo: Kuguquko lwequadrant, enye iaxis ihamba ngesona santya sesondlo siphezulu kwaye enye iaxis ime. Ke ngoko, indlela eyahlukileyo yokuziphatha yee-axe ezimbini inokukhokelela kwiimpazamo zecontour. Imbuyekezo yempazamo yequadrant inokunciphisa ngempumelelo le mpazamo kwaye iqinisekise iziphumo ezigqwesileyo zomatshini. Ubuninzi bee-pulses zembuyekezo bunokusetwa ngokuhambelana ne-acceleration-dependent characteristic curve, enokuthi igqitywe kwaye ifakwe kwi-parameterized ngovavanyo lokujikeleza. Ngexesha lovavanyo lokujikeleza, ukutenxa phakathi kweyona ndawo ikhoyo yekhontare yesetyhula kunye neradiyasi ecwangcisiweyo (ingakumbi ngexesha lothutho) irekhodwa ngokobungakanani kwaye iboniswe ngegraphical kwi-HMI. Kwinguqulelo entsha yesoftware yenkqubo, umsebenzi odityanisiweyo wembuyekezo oguqukayo unokwenza imbuyekezo eguquguqukayo ngokuhambelana nokuziphatha kwe-friction yesixhobo somatshini ngezantya ezahlukeneyo, ukunciphisa eyona mpazamo yecontour yomatshini kunye nokufezekisa ukuchaneka kokulawula okuphezulu.

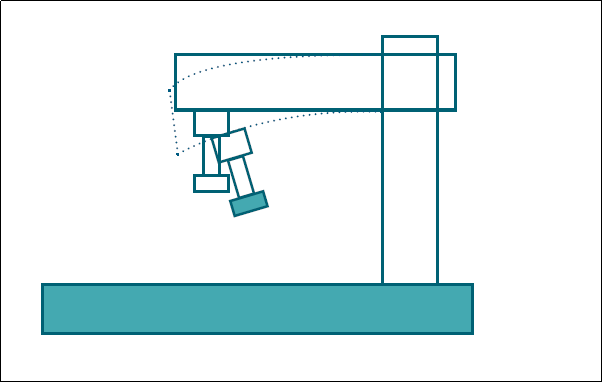

Imbuyekezo yempazamo yeSag kunye neAngle

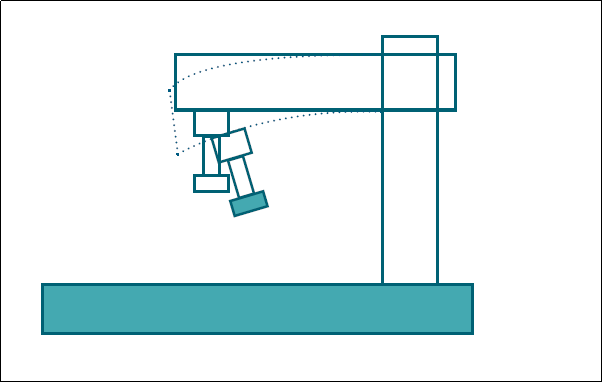

Imbuyekezo ye-Sag iyafuneka ukuba ubunzima bamalungu omatshini ngamnye bubangela ukuba iindawo ezihambayo zihambe kwaye zithobe, njengoko kubangela ukuba iindawo zomatshini ezihambelanayo, kubandakanywa nenkqubo yesikhokelo, zigxumeke. Imbuyekezo yempazamo ye-angular isetyenziswa xa ii-axes ezihambayo zingalungelelaniswanga enye kwenye kwi-engile echanekileyo (umzekelo, nkqo). Njengoko i-offset ye-position ye-zero isanda, kunjalo nempazamo yendawo. Zombini ezi mpazamo zibangelwa ubunzima obufileyo besixhobo somatshini, okanye ubunzima besixhobo kunye nomsebenzi. Amaxabiso embuyekezo alinganiswe ngexesha lokugunyaziswa alinganiswe kwaye agcinwe kwi-SINUMERIK ngokwesikhundla esihambelanayo kwindlela ethile, njengetafile yembuyekezo. Xa isixhobo somatshini sisebenza, indawo ye-axis efanelekileyo ifakwe ngokwexabiso lembuyekezo yendawo egciniweyo. Kwindlela nganye eqhubekayo, kukho iziseko kunye nembuyekezo. Ubushushu bembuyekezo yobushushu bunokubangela ukuba iindawo zomatshini zande. Uluhlu lokwandiswa luxhomekeke kwiqondo lokushisa, i-thermal conductivity, njl. Icandelo ngalinye lomatshini. Amaqondo obushushu ahlukeneyo anokubangela ukuba indawo yokwenene ye-axis nganye itshintshe, enokuthi ichaphazele kakubi ukuchaneka komsebenzi owenziwe ngoomatshini. Olu tshintsho lwexabiso lwangempela lunokulungiswa ngembuyekezo yeqondo lokushisa. Iigophe zempazamo kwi-axis nganye kumaqondo obushushu ahlukeneyo zinokuchazwa. Ukuze uhlale uhlawulela ukwanda kwe-thermal ngokuchanekileyo, ixabiso lembuyekezo yeqondo lokushisa, indawo yereferensi kunye neeparamitha ze-angle ye-gradient angle kufuneka ziqhubeke zidluliselwe kwakhona ukusuka kwi-PLC ukuya kulawulo lwe-CNC ngokusebenzisa iibhloko zokusebenza. Utshintsho lweparameter olungalindelekanga lupheliswa ngokuzenzekelayo yinkqubo yokulawula ukuphepha ukulayisha ngaphezulu komatshini kwaye kusebenze imisebenzi yokubeka iliso.