Izangqa zepiston zinezixhobo ezininzi ezahlukeneyo kunye neempawu ezahlukeneyo. Ukukhethwa kwempahla ye-piston kufuneka kuthathelwe ingqalelo iimeko zayo zenkonzo, iimfuno zokusebenza, uhlobo lwendandatho kunye nezinye izinto. Ngokubanzi, izixhobo zeringi yepiston ye-injini yokutsha yangaphakathi iya kuhlangabezana nezi mfuno zilandelayo:

1. Amandla aphezulu ngokwaneleyo oomatshini kwiqondo lokushisa eliphezulu

2. Gqoka ukuxhathisa kunye ne-coefficient ephantsi ye-friction

3. Akukho lula ukuvelisa i-adhesion kwaye kulula ukubaleka kuyo

4. Ukulungiswa kukulungele kwaye ixabiso liphantsi

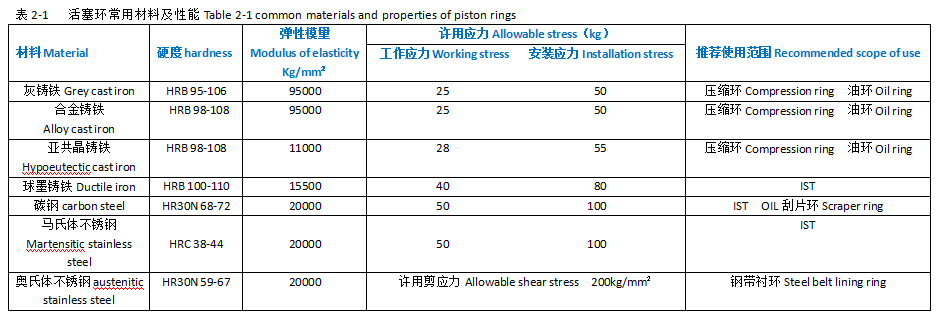

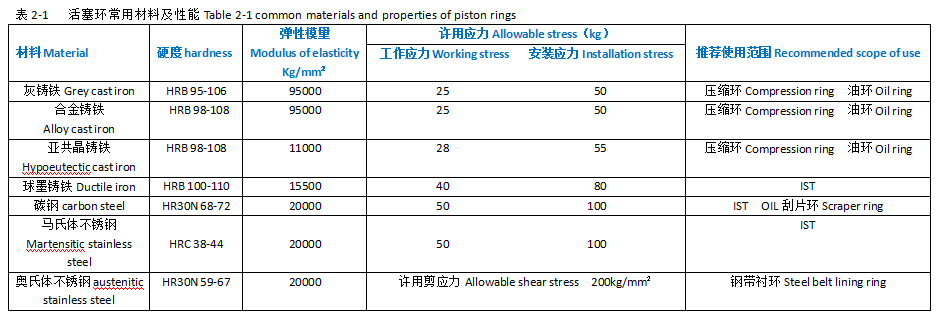

Ngale ndlela, i-piston ring material iyadingeka ukuba ibe namandla athile, ukuqina, ukuqina, ukuxhathisa (kubandakanywa nokugcinwa kweoli), ukumelana nokugqwala, ukuzinza kwe-thermal kunye nokuqhubekeka. Okwangoku, izinto zeringi yepiston ziyintsimbi ephoswe kakhulu. Ngokuqiniswa kwe-injini, kukho umkhwa wokutshintsha ukusuka kwintsimbi engwevu ukuya kwintsimbi ekhatywayo ethambileyo, intsimbi ephoswe ngamaqhuqhuva kunye nentsimbi. Jonga i-table 2-1 kwizinto eziqhelekileyo kunye neempawu.

Itheyibhile 2-1 izinto eziqhelekileyo kunye neepropati zamakhonkco episton

Nangona kunjalo, intshayelelo yanamhlanje ayingomsesane wepiston wezinto eziqhelekileyo, kodwa yintsimbi ye-ceramic composite film piston ring (i-ceramic infiltrated piston ring okanye i-ceramic metal piston ring for short), emva koku kubhekiselwa kuyo njengeringi ye-ceramic piston.

Izangqa zeCermet piston zenziwe ngokungena kwi-boron nitride (inxalenye yetyhubhic boron nitride) iiseramikhi ezinomsebenzi wokuzithambisa kumaleko womphezulu wepiston umsesane wokukhuhlana kweperi kubushushu obuphantsi (ngaphantsi kwama-200 ℃) ngokusebenzisa umphunga wekhemikhali weplasma* ophucukileyo. itekhnoloji yokubeka", ukwenzela ukuba umaleko womphezulu wokusebenza wamakhonkco episton yiceramic. Amakhonkco episton emva kokungeniswa kwe-ceramic anokumelana nokunxiba kakuhle, ukumelana nokunxiba kunye nokuxhathisa ukubola, Ke ngoko, ubomi benkonzo yeringi yepiston bunokuphuculwa. I-ceramic ehlanganisiweyo ifakwe kumphezulu weringi yepiston ngeplasma yekhemikhali yokubeka umphunga, eyahlukileyo kwinkqubo yokutshiza nge-ceramic phezu kwamanye amakhonkco episton. Le ndlela yenkqubo inokwenza izinto ezidibeneyo ze-ceramic zibe namandla okudibanisa ngokuqinileyo kunye nomphezulu weringi yepiston ngaphandle kokuqhekeka kunye nokuwa.

Ukongezelela, i-cermet composite layer ine-electronic structure efana ne-rhodium, ngoko inokuqhuba i-Catalysis yokuBasa kwi-injini kwaye inciphise kakhulu umxholo wokukhutshwa kwe-CO kunye ne-HC. Ke ngoko, amakhonkco e-ceramic afakwe kwi-piston nawo anefuthe elinamandla.

Itekhnoloji ye "Cermet composite film" yaphumelela * uvavanyo ngo-1997.

Izangqa zepiston ezifakwe kwi-Ceramic zisetyenziswe ngokubanzi kwizityalo ezinkulu ze-injini ezinesiphumo esihle sokusetyenziswa.

Yenza "i-ceramics esebenzayo" ehlanganiswe nesinyithi, eneempawu ezibalaseleyo zobunzima obuphezulu bomhlaba, i-coefficient ephantsi yokukhuhlana, ukunciphisa ukunxiba kunye nobomi obude benkonzo.

Kwiqondo lobushushu eliphantsi (ngaphantsi kwe-200 ℃), i-nitride (izinto ezihlanganisiweyo ze-ceramic) zingeniswa kumphezulu wesixhobo nge-plasma yekhemikhali yokubeka umphunga.

Iimbonakalo:

1. Ukukhula kobushushu obuphantsi. Xa ubushushu bokwenza ifilimu bungaphantsi kwama-200 ℃, aluyi konakalisa i-substrate kunye nomphezulu we-workpiece, okanye ukuguqula i-workpiece, kwaye ayiyi kuchaphazela ukuchaneka komatshini kunye nokusebenza kwendibano.

2. Uqhagamshelwano luqinile. Ngenxa yokuba isinyithi sisasazeka nge-boron nitride kunye ne-cubic boron nitride kwimeko ye-vacuum plasma ukwenza ukulahla izinto ezisebenzayo zegradient, iifilimu ezidibeneyo aziyi kuxobuka kubushushu obuphezulu okanye impembelelo.

3. Bobabini ubunzima kunye nokuqina kuphuculwe. Ngenxa yokusasazwa kwamanqanaba amabini efilimu edibeneyo kunye nesinyithi ukwenza izinto ezisebenzayo ezithambekele kwi-gradient, ayidlali kuphela indima yodibaniso oluqinileyo lomaleko wenguqu, kodwa ikwaphucula amandla okubopha, amandla okuqina kunye nokumelana nokugoba kweceramic, kunye nokuqina kwayo. idlula le yeceramic ngokwayo.

4. Ukumelana nokunxiba kakuhle kwiqondo lokushisa eliphezulu. Iziphumo zovavanyo zibonisa ukuba xa kuthelekiswa nokucwenga kwechromium, ubulukhuni befilimu ehlanganisiweyo bunyuka kakhulu ngokunyuka kwamaqondo obushushu kwimo engqongileyo eyi-250 ℃ - 350 ℃, kwaye ubunzima bomphezulu bunyuka ngaphezu kwe-hv210, ngelixa i-chromium eqinile iyancipha kakhulu emva kovavanyo. 250 ℃, kwaye yehla malunga ne-hv110 kuma-350 ℃. Ke, xa kuthelekiswa nomsebenzi ngaphandle kokufakwa kwefilimu edibeneyo, i-ceramic plated workpiece inokumelana nokunxiba ngcono kwindawo yobushushu obuphezulu.

5. Ukuxhathisa okuqinileyo kwe-oxidation. Iziphumo zovavanyo zibonisa ukuba ifilim ehlanganisiweyo isenokumelana ne-oxidation elungileyo kunye nokumelana ne-asidi-base xa ubushushu bungaphezulu kwe-1000 ℃.

6. Inomsebenzi we-oxidation kunye ne-catalysis. Xa i-ceramic ingena kumphezulu wesinyithi, ubungakanani obufanelekileyo besithuba se-electron senziwa, esenza ukuba ifilimu edibeneyo ibe nempembelelo ye-oxidation catalytic kwi-CO kunye ne-HC, kwaye inciphisa kakhulu ungcoliseko oluphumayo lwe-injini.

7. Ukusebenza kakuhle kokujija kunye ne-plating. Iifilimu ezihlanganisiweyo ziyikhemikhali yokubeka umphunga, ngoko ke iifilimu ezihlanganisiweyo zinokukhuliswa naphi na apho irhasi inokudlula khona, kwaye iimeko zokusetyenzwa azikhawulelwanga kukumila kunye nokuma kwendawo yokusebenza.

8. Iinkalo zesicelo ezibanzi. Ukongeza ekusetyenzisweni kwi-injini, ifilimu edibeneyo ifanelekile kwizibini zokukhuhlana koomatshini abahlukeneyo, ubushushu obuphezulu kunye neendawo ezinganyangekiyo kwi-corrosion, izixhobo ezahlukeneyo zokusika kunye nokubumba, kwaye ziyakwazi ukuziqhelanisa nezixhobo ezahlukeneyo zetsimbi okanye ezingezizo ezentsimbi. iiparameters zenkqubo ezahlukeneyo.