Quenching na tempering of crankshafts

2020-01-16

Prosés quenching jeung tujuan

workpiece nu dipanaskeun nepi ka suhu austenitizing pikeun kurun waktu nu tangtu lajeng leuwih tiis dina laju leuwih gede ti laju cooling kritis pikeun ménta prosés perlakuan panas tina struktur martensite.

Pikeun ningkatkeun karasa luhur sareng résistansi ngagem tina workpiece

Prosés tempering suhu rendah sareng tujuanana

Hiji prosés perlakuan panas nu baja quenched dipanaskeun dina 250 ° C. lajeng leuwih tiis.

Dina raraga ngajaga teu karasa luhur sarta lalawanan ngagem tina workpiece quenched, ngurangan setrés residual jeung brittleness salila quenching.

Kumaha carana ngabedakeun crankshaft quenched na unquenched?

Beusi ngaréaksikeun kimiawi jeung oksigén dina hawa dina suhu luhur pikeun ngahasilkeun trioksida beusi hideung. Ieu béda ti naon anu biasa urang sebut karat. Anu biasana urang sebutkeun ngeunaan karat nyaéta beusi ngaréaksikeun sareng oksigén, cai, sareng zat-zat sanés dina hawa dina suhu kamar ngabentuk (komponén utama karat) oksida beusi, beureum.

Beusi dipanaskeun dina oksigén:

3Fe + 2O2 === Pemanasan ==== Fe3O4

Beusi karat dina hawa:

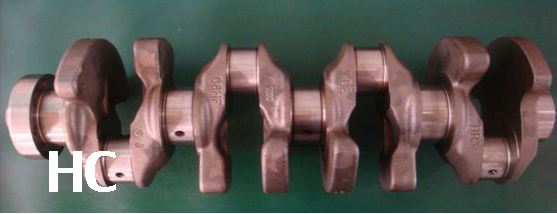

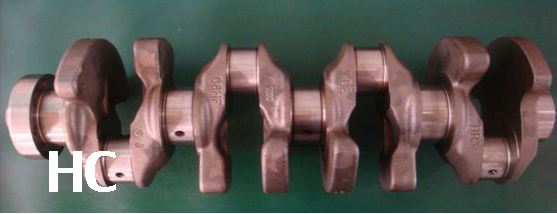

crankshaft unquenched

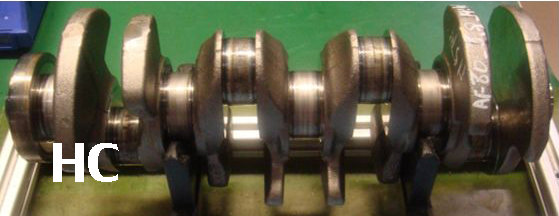

crankshaft quenched