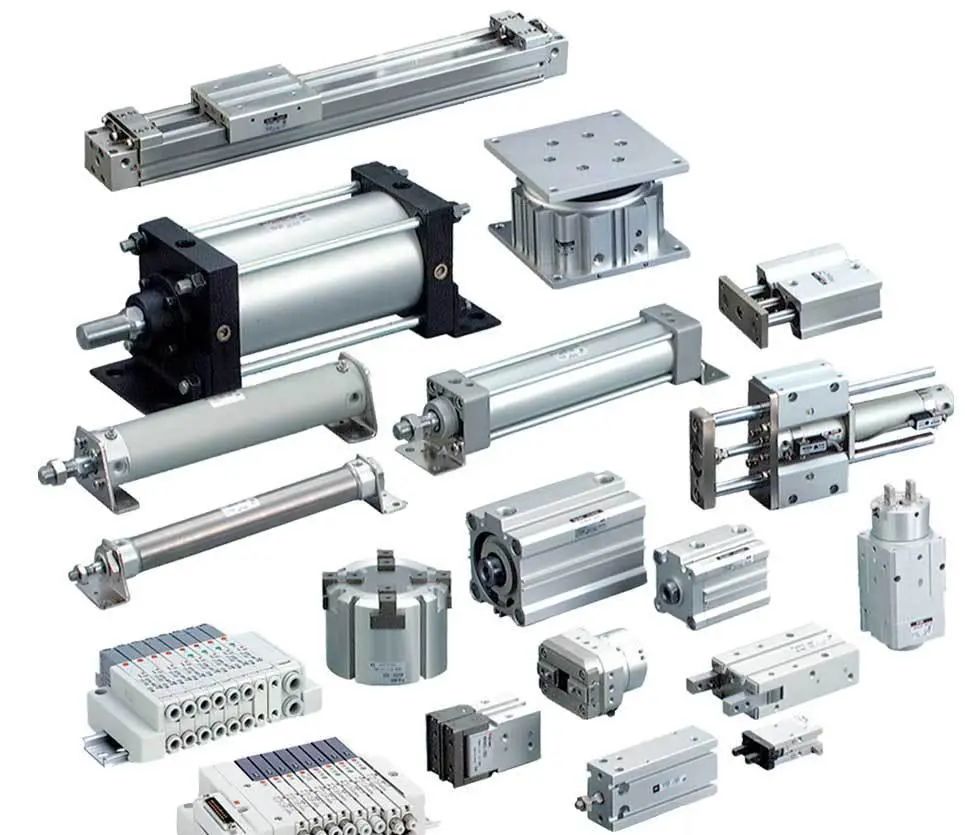

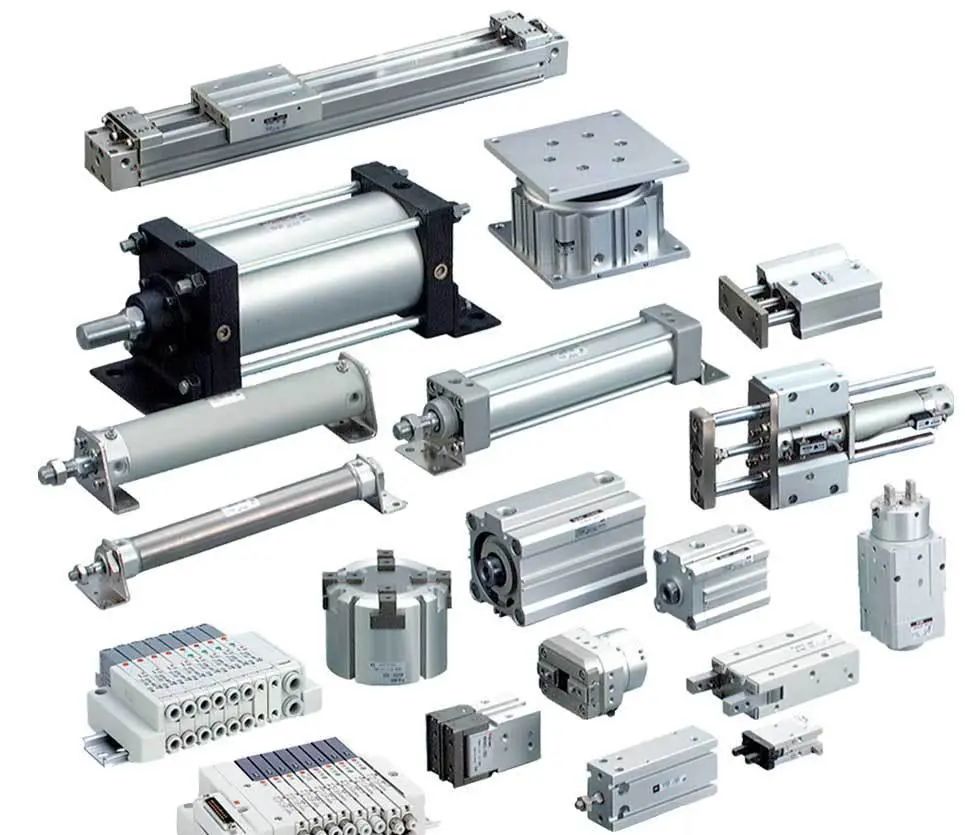

1. Kusarudzwa kwemhando

Zvinoenderana nezvinodiwa zvekushanda uye mamiriro, sarudza nemazvo rudzi rwe cylinder. Kana silinda ichidikanwa kusvika kumagumo ekurohwa pasina kukanganisa uye ruzha rwekukanganisa, buffer cylinder inofanira kusarudzwa; kana zvichidiwa kuti ive yakareruka muhuremu, silinda yechiedza inofanira kusarudzwa; kana zvichidikanwa kuti ive nenzvimbo yakamanikana yekuisa uye kupfupika kwepfupi, cylinder yakaonda inogona kusarudzwa; kana pane lateral load, cylinder ine tsvimbo yemutungamiri inogona kusarudzwa; Kana iyo chaiyo braking yakakwirira, silinda yekuvhara inofanira kusarudzwa; kana tsvimbo yepiston isingabvumirwi kutenderera, cylinder ine basa risina kutenderera retsvimbo rinogona kusarudzwa; munzvimbo yakakwirira yekushisa, silinda inodzivirira kupisa inofanira kusarudzwa; munzvimbo inotyisa, cylinder isingadziviriri inofanira kusarudzwa. Munzvimbo dzakaomarara dzakadai seguruva, zvinodikanwa kuisa chifukidziro cheguruva pamucheto unobuda wepiston tsvimbo. Kana pasina kusvibiswa kunodiwa, zvinodikanwa kuti usarudze-isina-oiri-isina-oiri-isina-isina lubricated cylinders, nezvimwe.

2. Fomu yekuisa

Izvo zvinoenderana nezvinhu zvakadai sekuisa nzvimbo uye chinangwa chekushandisa. Kazhinji, silinda yakagadziriswa inoshandiswa. Kana zvichidikanwa kutenderera nguva dzose nemaitiro ekushanda (akadai sema lathes, grinders, nezvimwewo), cylinder inotenderera inofanira kusarudzwa. Kana iyo piston tsvimbo ichidikanwa kuita arc swing mukuwedzera kune mutsara kufamba, pivot pini silinda inosarudzwa. Kana pane zvakakosha zvinodiwa, silinda yakakosha inofanirwa kusarudzwa. Iyo yeruzhinji account "Mechanical Engineering Literature", chiteshi chepeturu chemainjiniya!

3. Kukura kwesimba

Ndiko, kusarudzwa kwebhore dhayamita. Sarudza kusunda uye kudhonza simba rinobuda necylinder zvinoenderana nesimba rekuremedza. Kazhinji, simba rehumburumbira rinodiwa neiyo theoretical balance mamiriro emutoro wekunze rinoshandiswa, uye mitero yakasiyana-siyana inosarudzwa maererano nekumhanya kwakasiyana, kuitira kuti simba rekubuda resilinda rive nemiganhu shoma. Kana iyo cylinder dhayamita yakanyanya kudiki, simba rekubuda harina kukwana, asi kana iyo cylinder dhayamita yakakura kwazvo, midziyo ichave yakakura, mutengo uchawedzera, uye kushandiswa kwemhepo kuchawedzerwa, izvo zvinoparadza simba. Mukugadzirisa kwekugadzirisa, nzira yekuwedzera inofanira kushandiswa zvakanyanya sezvinobvira kuderedza hukuru hwehumburumbira.

4. Piston sitiroko

Iyo ine hukama nechiitiko chekushandiswa uye sitiroko yemuchina, asi kazhinji sitiroko yakazara haina kusarudzwa kudzivirira piston kubva pakudhumhana nemusoro wecylinder. Kana ichishandiswa pakugadzirisa mashandiro, zvichingodaro, muganho we10-20mm unofanirwa kuwedzerwa zvinoenderana nesitiroko inodiwa pakuverenga.

5. Kumhanya kwepiston

Izvo zvinonyanya kuenderana neiyo yekupinza yakadzvanywa mhepo yekuyerera mwero wecylinder, saizi yekutora uye exhaust ports ye silinda uye dhayamita yemukati yemugero. Inodiwa kutora kukosha kukuru kwekufambisa-kumhanya-mhanya. Silinda yekufamba kumhanya inowanzoita 50-800mm/s. Kune ma-cylinders e-high-speed motion cylinders, pombi yekutora ine dhayamita yakakura yemukati inofanira kusarudzwa; nokuda kwekuchinja kwemutoro, kuitira kuti uwane inononoka uye yakagadzikana yekufambisa kukurumidza, chigadziro chinoputika kana gas-liquid damping cylinder inogona kushandiswa, iyo iri nyore kuwana kukurumidza kutonga. Paunosarudza throttle valve kuti udzore kukurumidza kwe cylinder, kutarisa kunofanira kubhadharwa kune: apo cylinder yakasungirirwa yakadzika inosundira mutoro, inokurudzirwa kushandisa mhepo inoputika kugadzirisa kukurumidza; apo silinda yakagadzikwa yakasimudzwa inosimudza mutoro, zvinokurudzirwa kushandisa mhepo inotora throttling kugadzirisa kumhanya; kufamba pamagumo ekurohwa kunodiwa kuve kwakatsetseka Paunenge uchidzivirira kukanganisa, silinda ine buffer mudziyo inofanira kusarudzwa.