Kutsauka kwakabatana nemuchina wezvishandiso zvemuchina zvinogona kurekodhwa zvakarongeka, asi misiyano inogona kuramba ichioneka kana kuwedzera panguva yekushandiswa kunotevera nekuda kwemamiriro ekunze akadai setembiricha kana kurema kwemuchina. Muzviitiko izvi, SINUMERIK inogona kupa mabasa akasiyana ekubhadhara. Ripira kutsauswa uchishandisa zviyero kubva kune chaiwo maencoder echinzvimbo (eg magirating) kana mamwe masensor (eg laser interferometers, nezvimwewo) kune zvirinani machining mhedzisiro. Muchinyorwa chino, tichasuma zvinowanzoitika muripo mabasa eSINUMERIK. Inoshanda SINUMERIK yekuyera ma cycles akadai se "CYCLE996 Motion Measurement" inogona kupa tsigiro yakazara yevashandisi vekupedzisira panguva yekuenderera mberi kwekutarisa uye kugadzirisa kwemuchina maturusi.

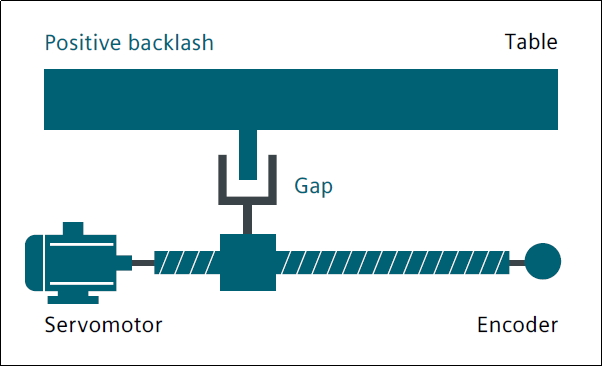

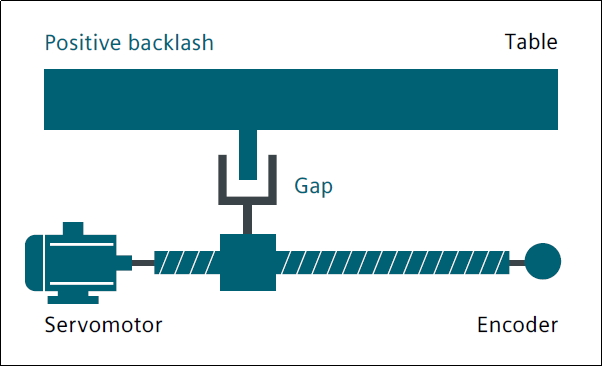

Backlash compensation

Kupindirana kana kunonoka kutapurirana kwesimba kunoitika pakati pezvikamu zvinofamba zvechishandiso chemuchina uye nhengo dzayo dzekutyaira, senge bhora screws, nekuti dhizaini isina mapeji inowedzera zvakanyanya kupera kwechishandiso chemuchina, uye zvakare zvakaoma kuwana maererano. zveteknolojia. . Mechanical play inotungamira mukutsauka pakati pemafambiro nzira dzematemo/spindles uye akayerwa kukosha kweiyo isina kunanga yekuyera sisitimu. Izvi zvinoreva kuti kana chitarisiko chashandurwa, axis inoenda kure kana kuswedera zvakanyanya, zvichienderana nekukura kwegap. Tafura uye maencoder ayo anobatanidzwa zvakare anokanganisa: kana iyo encoder iri pamberi petafura, inosvika panzvimbo yakarairwa kare zvinoreva kuti muchina unofamba daro rakaderera. Kana muchina uchinge uchimhanya, nekushandisa backlash muripo webasa pane inoenderana axis, iyo yakamborekodhwa kutsauka inogadziriswa otomatiki panguva yekudzokera kumashure, ichipfuura yakamborekodhwa kutsauka pane chaiyo chinzvimbo kukosha.

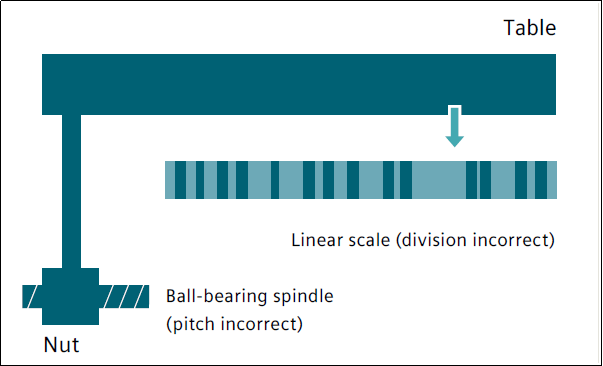

Lead screw pitch error compensation

Nheyo yekuyera yechiyero chisina kunanga muCNC control system yakavakirwa pafungidziro yekuti nhanho yebhora screw inoramba isina kuchinjika mukati meiyo sitiroko inoshanda, saka nedzidziso, iyo chaiyo chinzvimbo cheiyo mutsara axis inogona kutorwa kubva kune inofamba ruzivo chinzvimbo cheiyo dhiraivha mota. Nekudaro, kukanganisa kwekugadzira mumabhora screws kunogona kukonzera kutsauka muyero sisitimu (inozivikanwawo se lead screw pitch errors). Dambudziko iri rinogona kuwedzererwa nekumisikidzwa kwechiyero (zvichienderana nechiyero chekuyera chinoshandiswa) uye kukanganisa kwekuisa kweyero system pamushini (inozivikanwawo sekuyerwa system kukanganisa). Kuti utsivise marudzi maviri aya ekukanganisa, yakazvimirira yekuyera sisitimu (laser kuyerwa) inogona kushandiswa kuyera yakasikwa kukanganisa curve yemuchina weCNC muchina, uye ipapo kukosha kwemuripo kunochengetwa muCNC system yemuripo.

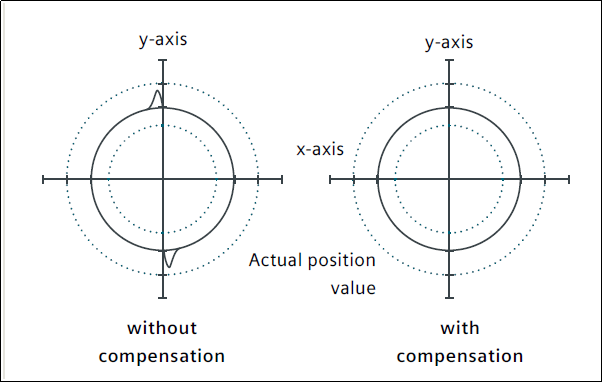

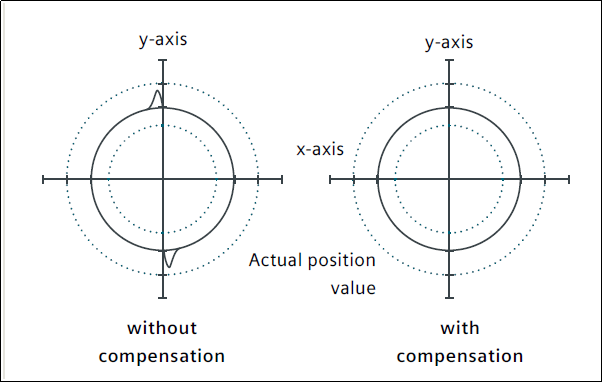

Friction compensation (quadrant error compensation) uye dynamic friction compensation

Quadrant Error Compensation (inozivikanwawo seFriction Compensation) inokodzera zvese zviri pamusoro kuitira kuti uvandudze zvikuru iko contour kana uchigadzira denderedzwa contours. Chikonzero ndeichi: Mushanduko yequadrant, imwe axis iri kufamba nepamusoro-soro rekudya uye imwe axis yakamira. Naizvozvo, hunhu hwakasiyana hwekukweshana kwemasemo maviri hunogona kutungamira mukukanganisa kwe contour. Quadrant kukanganisa kubhadharwa kunogona kunyatso kudzikisa chikanganiso ichi uye kuve nechokwadi chakanakisa machining mhedzisiro. Iyo density yemapulses ekubhadhara inogona kusetwa zvinoenderana nekumhanyisa-inotsamira hunhu curve, iyo inogona kutsanangurwa uye parametered neyakatenderera bvunzo. Panguva yekuyedzwa kwekutenderera, kutsauka pakati penzvimbo chaiyo yedenderedzwa contour uye yakarongwa radius (kunyanya panguva yekufamba) inorekodhwa uwandu uye inoratidzwa zvakajeka paHMI. Paiyo vhezheni itsva yesoftware software, iyo yakasanganiswa inoshanduka friction muripo inogona kuita muripo une simba zvinoenderana nekuita kwekukwenya kwechishandiso chemuchina nekumhanya kwakasiyana, kudzikisa iko iko iko kukanganisa contour uye kuwana yakakwirira kutonga chaiko.

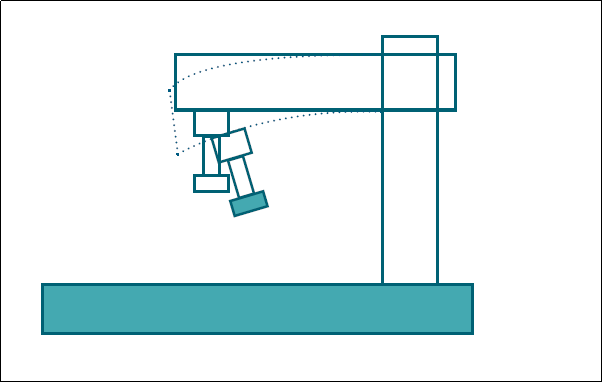

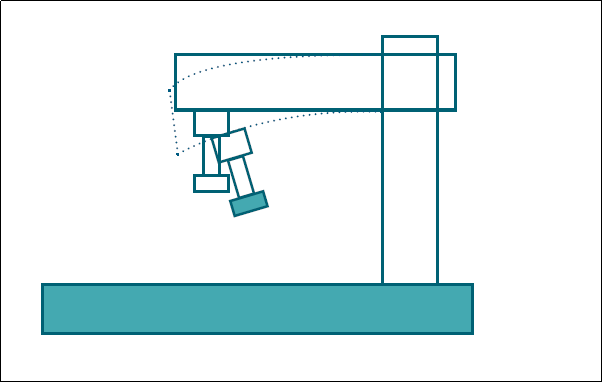

Sag uye Angle Error Muripo

Sag muripo unodiwa kana huremu hwemakina ega ega zvikamu zvichiita kuti zvikamu zvinofamba zvifambe uye zvirereke, sezvo zvichikonzeresa kuti zvikamu zvemuchina zvakabatana, kusanganisira dhizaini, kudonha. Angular error compensation inoshandiswa kana mbezo dziri kufamba dzisina kurongeka pakona chaiyo (eg vertical). Sezvo kubviswa kweiyo zero kunowedzera, ndizvo zvinoitawo kukanganisa kwenzvimbo. Zvose zvikanganiso izvi zvinokonzerwa nehuremu hwakafa hwemuchina, kana huremu hwechishandiso uye workpiece. Mari yekubhadhara yakayerwa panguva yekutumwa inoverengerwa uye inochengetwa muSINUMERIK zvichienderana nenzvimbo inoenderana mune imwe fomu, senge tafura yemuripo. Kana chishandiso chemuchina chiri kushanda, chinzvimbo cheiyo axis yakakodzera inopindirwa zvichienderana nekukosha kwekubhadharwa kwenzvimbo yakachengetwa. Kune yega yega nzira inoenderera inofamba, kune ekutanga uye muripo wematemo. Tembiricha yekubhadhara kupisa kunogona kukonzera kuti zvikamu zvemuchina zviwedzere. Uwandu hwekuwedzera hunoenderana nekupisa, kupisa conductivity, nezvimwe zvemuchina wega wega chikamu. Kupisa kwakasiyana kunogona kuita kuti nzvimbo chaiyo yeakisi imwe neimwe ichinje, izvo zvinogona kukanganisa kurongeka kweiyo workpiece iri kuitwa. Idzi shanduko chaidzo dzekukosha dzinogona kudzikiswa nekubhadharwa kwetembiricha. Mhosho dzemacurves eimwe axis patembiricha dzakasiyana dzinogona kutsanangurwa. Kuti ugare uchibhadhara kuwedzera kwemafuta nenzira kwayo, iwo tembiricha muripo wemuripo, chinzvimbo chereferensi uye mutsara gradient angle paramita dzinofanira kuramba dzichitamiswa kubva kuPLC kuenda kuCNC kutonga kuburikidza nemabhuroki ebasa. Kusatarisirwa parameter shanduko inobviswa otomatiki neiyo control system kudzivirira kuwandisa muchina uye activate yekutarisa mabasa.