Zvindori zvepiston zvine zvakasiyana-siyana zvezvinhu uye zvakasiyana siyana. Kusarudzwa kwepiston ring material kunofanirwa kutarisa mamiriro ayo ebasa, maitiro ekuita, mhando yemhete nezvimwe zvinhu. Kazhinji kutaura, iyo piston mhete yemukati injini yekupisa ichazadzisa zvinotevera zvinodiwa:

1. Yakakwirira zvakakwana simba remagetsi pakupisa kwepamusoro

2. Pfeka kuramba uye yakaderera friction coefficient

3. Hazvisi nyore kugadzira adhesion uye nyore kumhanya mukati

4. Kugadziriswa kuri nyore uye mutengo wakachipa

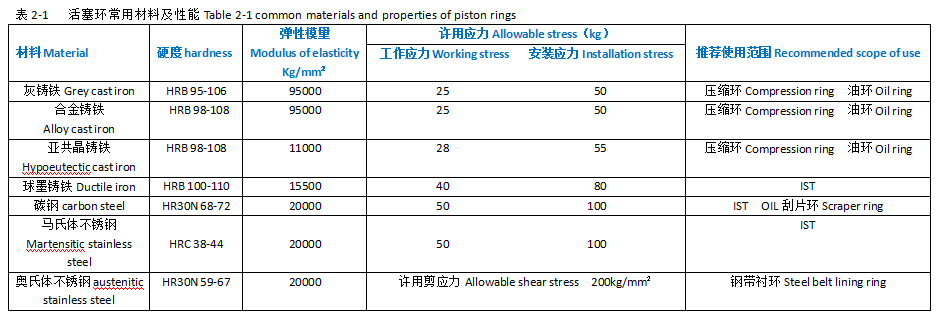

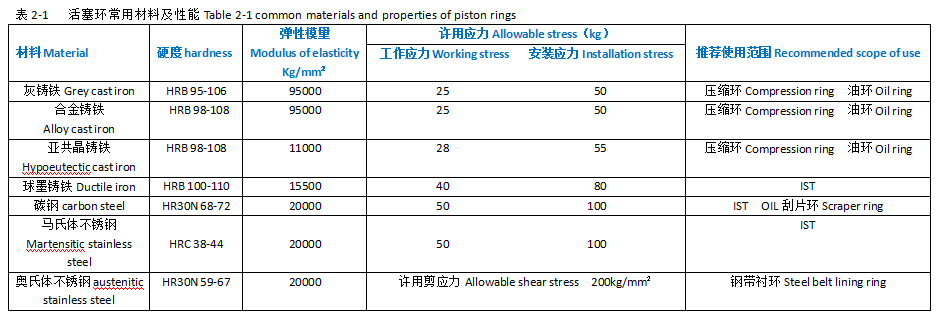

Nenzira iyi, iyo piston mhete zvinhu inodiwa kuti ive nehumwe simba, kuoma, elasticity, kupfeka kuramba (kusanganisira kuchengetedza mafuta), corrosion kuramba, kugadzikana kwemafuta uye processability. Parizvino, zvinhu zvepiston mhete inonyanya kukanda simbi. Nekusimbaradzwa kweinjini, pane maitiro ekuchinja kubva grey cast iron kuenda kune inogadzika simbi yakakandwa, nodular cast iron uye simbi. Ona tafura 2-1 yezvakajairwa zvinhu uye zvivakwa.

Tafura 2-1 zvinhu zvakajairika uye zvimiro zvepiston zvindori

Nekudaro, sumo yemazuva ano haisi yepiston mhete yezvinhu zvakajairika, asi simbi ye ceramic composite film piston ring (ceramic infiltrated piston ring kana ceramic metal piston ring for short), inozonzi simbi ceramic piston ring.

Cermet piston zvindori zvinogadzirwa nekupinza boron nitride (chikamu che cubic boron nitride) ceramics ine * self-lubricating basa mukati mepamusoro pepiston ring friction pair pakudziya kwakaderera (pasi pe200 ℃) nekushandisa yenyika * yepamusoro "plasma chemical vapor. deposition tekinoroji", kuitira kuti iyo yekushanda pamusoro peiyo mhete yepiston ndeye ceramic. Zvindori zvepiston mushure mekupinzwa kweceramic zvine kumira zvakanaka kwekupfeka, kupfeka kuramba uye kushorwa kwekuora, Naizvozvo, hupenyu hwesevhisi yepiston mhete inogona kuvandudzwa. Iyo composite ceramic inopinzwa mukati mepamusoro pepiston mhete neplasma kemikari vapor deposition, iyo yakasiyana neyeceramic spraying process pamusoro pemamwe mapiston mhete. Iyi nzira yekugadzira inogona kuita kuti iyo composite ceramic zvinhu ive yakasimba yekubatanidza simba nepamusoro pepiston mhete isina kutsemuka nekudonha.

Mukuwedzera, iyo cermet composite layer ine chimiro chemagetsi chakafanana nerhodium, saka inogona kuita Combustion Catalysis muinjini uye kuderedza zvakanyanya kuburitsa kweCO neHC. Naizvozvo, ceramic impregnated piston mhete zvakare ine catalytic mhedzisiro.

"Cermet composite film" tekinoroji yakapfuura * ongororo muna 1997.

Ceramic impregnated piston mhete dzave dzichishandiswa zvakanyanya mumainjini makuru zvidyarwa zvine yakanaka application maitiro.

Iyo inoumba "functional ceramics" yakasanganiswa nesimbi, iyo ine hunhu hwakatanhamara hwekuoma kwepamusoro pepamusoro, kuderera kwekukwenya coefficient, kuderedza kupfeka uye hupenyu hurefu hwebasa.

Pakupisa kwakadzika (pasi pe200 ℃), nitride (composite ceramic material) inopinzwa mumudziyo wemidziyo neplasma kemikari vapor deposition.

Features:

1. Kuderera kwekushisa kwekukura. Kana tembiricha yekugadzira firimu iri pazasi pe200 ℃, haizokuvadza iyo substrate uye pamusoro peiyo workpiece, kana kukanganisa workpiece, uye haizokanganisa machining kurongeka uye kuita kwegungano.

2. Kubatana kwakasimba. Nekuda kwekuti simbi inopararira neboron nitride uye cubic boron nitride iri munzvimbo yevacuum plasma kuti igadzire kurasa zvinhu zvine gradient, mafirimu akaumbwa haabvire pakupisa kwakanyanya kana kukanganisa.

3. Zvose kuoma uye kuoma zvinovandudzwa. Nekuda kwekupararira kwezvikamu zviviri zvemusanganiswa firimu uye simbi kuumba yakarerekera gradient inoshanda zvinhu, haingoite basa rekusimba musanganiswa weiyo shanduko dhizaini, asi zvakare inovandudza kusimba kwekubatanidza, kusimba kwesimba uye kukotama kuramba kweceramic, uye kuoma kwayo. inodarika iyo ceramic pachayo.

4. Kuramba kwakanaka kupfeka pakupisa kwepamusoro. Mhedzisiro yekuedza inoratidza kuti kana ichienzaniswa nechromium plating, kuoma kwefirimu rinoumbwa kunowedzera zvakanyanya nekuwedzera kwekushisa munzvimbo ye250 ℃ - 350 ℃, uye kuoma kwepasi kunowedzera nekupfuura hv210, nepo chromium yakaoma ichiderera zvakanyanya mushure. 250 ℃, uye inodzikira neinenge hv110 pa350 ℃. Nekudaro, zvichienzaniswa neyeworkpiece isina composite firimu plating, iyo ceramic plated workpiece ine zvirinani kupfeka kuramba munzvimbo yepamusoro yekupisa.

5. Yakasimba oxidation kuramba. Mhedzisiro yekuedza inoratidza kuti iyo firimu inoumbwa ichine yakanaka oxidation kuramba uye acid-base kuramba kana tembiricha yakakura kupfuura 1000 ℃.

6. Iine basa re oxidation uye catalysis. Kana iyo ceramic ichipinda mukati mesimbi, huwandu hwakakodzera hweerekitironi vacancy inogadzirwa, izvo zvinoita kuti firimu rinoumbwa rive neoxidation catalytic mhedzisiro paCO neHC, uye inoderedza zvakanyanya kusvibiswa kwemhepo yeinjini.

7. Zvakanaka mhepo uye plating kushanda. Mafirimu eComposite ikemikari vapor deposition, saka mafirimu anoumbwa anogona kukura pese panogona kupfuura gasi, uye mamiriro ekugadzirisa haaganhurwe nechimiro uye chinzvimbo chebasa rekushanda.

8. Wide application fields. Pamusoro pekushandiswa kune injini, iyo inoumbwa firimu inokodzerawo kukweshana kwemakina akasiyana-siyana, yakakwirira-tembiricha uye inodzivirira ngura, maturusi akasiyana siyana ekucheka uye mold, uye inogona kuchinjika kune akasiyana simbi kana asiri-simbi zvinhu kuburikidza. akasiyana maitiro parameters.