Kupatuka kwadongosolo kumakina kwa zida zamakina kumatha kujambulidwa mwadongosolo, koma zopatuka zitha kuwonekabe kapena kuwonjezereka pakagwiritsidwe ntchito kotsatira chifukwa cha chilengedwe monga kutentha kapena kuchuluka kwa makina. Muzochitika izi, SINUMERIK ikhoza kupereka ntchito zosiyanasiyana zolipirira. Lipirani zopatuka pogwiritsa ntchito miyeso yochokera ku ma encoder enieni (monga ma gratings) kapena masensa owonjezera (monga ma laser interferometers, ndi zina zotero) kuti mupeze zotsatira zabwino za makina. M'magaziniyi, tikuwonetsani ntchito za chipukuta misozi za SINUMERIK. Zoyeserera za SINUMERIK zoyezera monga "CYCLE996 Motion Measurement" zimatha kupereka chithandizo chokwanira kwa ogwiritsa ntchito kumapeto panthawi yowunika ndikukonza zida zamakina.

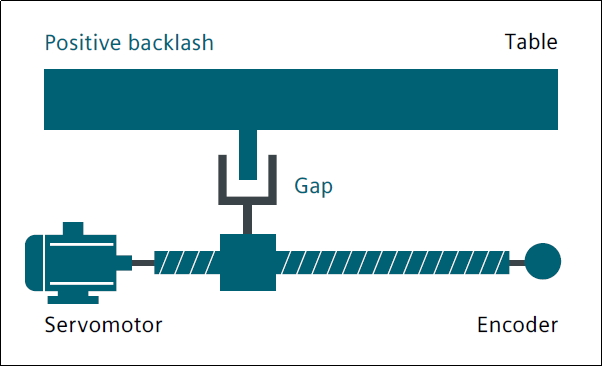

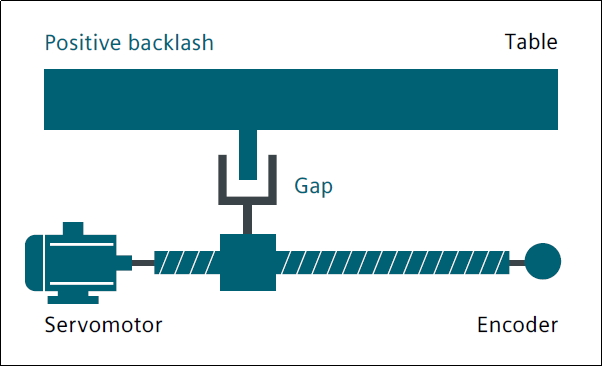

Kubweza kwa backlash

Kutumiza kwapakatikati kapena kuchedwa kwamphamvu kumachitika pakati pa magawo osuntha a chida cha makina ndi magawo ake oyendetsa, monga zomangira za mpira, chifukwa makina opangira mawotchi opanda mipata adzawonjezera kwambiri kuvala kwa chida cha makina, komanso kumakhala kovuta kukwaniritsa. zaukadaulo. . Kusewerera kwamakina kumabweretsa kupatuka pakati pa njira zoyenda za nkhwangwa/spindles ndi milingo yoyezera yanjira yosalunjika. Izi zikutanthauza kuti njirayo ikasinthidwa, olamulira adzasunthira kutali kwambiri kapena kuyandikira kwambiri, malinga ndi kukula kwa kusiyana. Gome ndi ma encoder ake ogwirizana nawo amakhudzidwa: ngati encoder ili patsogolo pa tebulo, imafika pomwe idalamulidwa kale zomwe zikutanthauza kuti makinawo amayenda mtunda wocheperako. Pamene makinawo akugwira ntchito, pogwiritsa ntchito chipukuta misozi cha backlash pa oxis yofananira, kupatuka komwe kunalembedwa kale kumangoyambika panthawi yosinthira, ndikuwongolera kupotoza komwe kunalembedwa kale pamtengo weniweni.

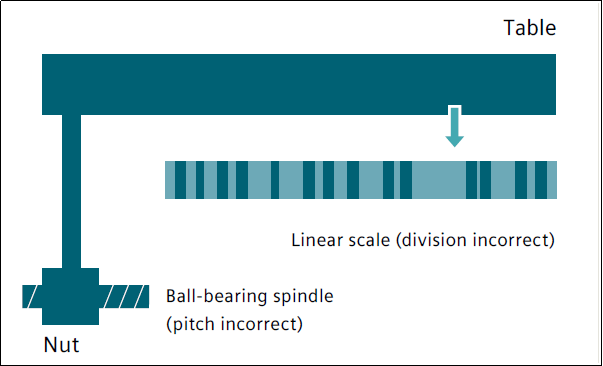

Kubweza zolakwika za screw pitch

Mfundo yoyezera yoyezera mosalunjika mu dongosolo lowongolera la CNC idakhazikitsidwa poganiza kuti phula la wononga mpira silinasinthidwe mkati mwa sitiroko yogwira mtima, kotero, mwachidziwitso, malo enieni a olamulira a mzere amatha kutengedwa kuchokera ku chidziwitso choyenda cha yendetsa galimoto. Komabe, zolakwika zopanga mu zomangira za mpira zimatha kupangitsa kuti pakhale zolakwika pamiyezo (yomwe imadziwikanso kuti lead screw pitch errors). Vutoli likhoza kukulirakulira chifukwa cha kusiyanasiyana kwa miyeso (malingana ndi njira yoyezera yomwe imagwiritsidwa ntchito) ndi zolakwika zoyika makina oyezera pamakina (omwe amadziwikanso kuti zolakwika zamakina). Pofuna kubwezera zolakwika zamitundu iwiriyi, njira yoyezera yodziyimira payokha (kuyezera laser) ingagwiritsidwe ntchito kuyeza zokhota zachilengedwe za chida cha makina a CNC, ndiyeno mtengo wolipiridwa umasungidwa mu dongosolo la CNC la chipukuta misozi.

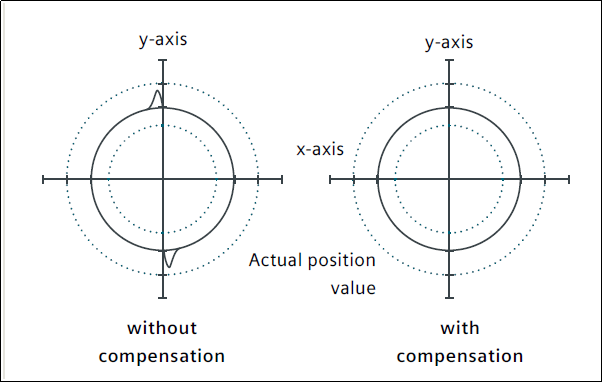

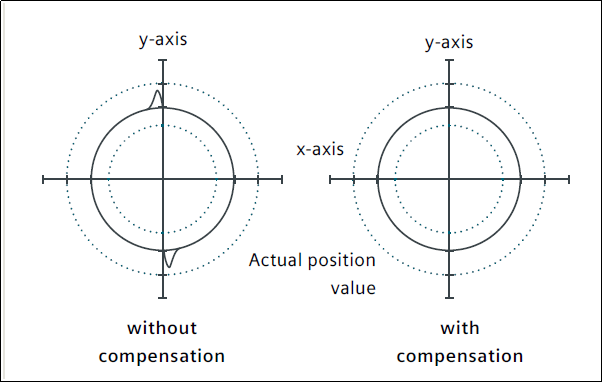

Kulipiritsa kwa friction (quadrant error compensation) ndi dynamic friction compensation

Quadrant Error Compensation (yomwe imadziwikanso kuti Friction Compensation) ndiyoyenera zonse zomwe zili pamwambapa kuti ziwongolere kulondola kwa mizere popanga mizere yozungulira. Chifukwa chake ndi chotere: Pakusintha kwa quadrant, olamulira amodzi akuyenda pamlingo wapamwamba kwambiri wa chakudya ndipo mbali ina imayima. Chifukwa chake, kukangana kosiyanasiyana kwa nkhwangwa ziwirizi kumatha kubweretsa zolakwika za contour. Malipiro olakwika a Quadrant amatha kuchepetsa cholakwikacho ndikuwonetsetsa zotsatira zabwino kwambiri zamakina. Kuchulukana kwa ma pulses amalipiro kumatha kukhazikitsidwa molingana ndi ma curve omwe amadalira ma curve, omwe amatha kutsimikiziridwa ndikuyesedwa ndi mayeso ozungulira. Pakuyesa kozungulira, kupatuka pakati pa malo enieni a contour yozungulira ndi radius yokonzedwa (makamaka panthawi yakusintha) kumajambulidwa mochulukira ndikuwonetseredwa pa HMI. Pa mtundu watsopano wa pulogalamu yamakina, ntchito yolipirira yokhazikika yokhazikika imatha kubweza chiwongola dzanja molingana ndi machitidwe amakina a chida cha makina pa liwiro losiyana, kuchepetsa cholakwika chenicheni cha makina a contour ndikukwaniritsa kulondola kwapamwamba.

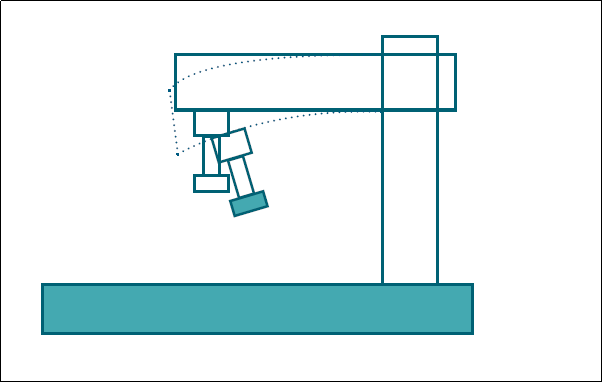

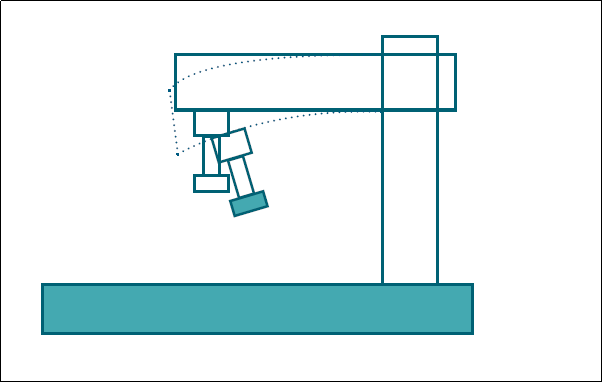

Malipiro Olakwika a Sag ndi Angle

Kulipira kwa Sag kumafunika ngati kulemera kwa magawo a makinawo kumapangitsa kuti magawo osuntha asunthike ndikupendekeka, chifukwa zimapangitsa kuti zida zamakina, kuphatikiza kalozera, zigwe. Kulipira kolakwika kwa angular kumagwiritsidwa ntchito ngati nkhwangwa zosuntha sizikugwirizana ndi ngodya yolondola (mwachitsanzo yoyimirira). Pamene kuchotsera kwa zero kuchulukira, momwemonso vuto la malo. Zolakwa zonsezi zimayambitsidwa ndi kulemera kwakufa kwa chida cha makina, kapena kulemera kwa chida ndi workpiece. Malipiro omwe amayezedwa panthawi yotumizidwa amawerengedwa ndikusungidwa mu SINUMERIK molingana ndi momwe amachitira mwanjira ina, monga tebulo lamalipiro. Pamene chida cha makina chikugwira ntchito, malo a olamulira oyenerera amalowetsedwa molingana ndi mtengo wamalipiro wa malo osungidwa. Panjira iliyonse yopitilira, pali nkhwangwa zolipirira. Kutentha kwamalipiro a kutentha kungapangitse kuti mbali za makinawo ziwonjezeke. Kukula kosiyanasiyana kumadalira kutentha, kutentha kwa matenthedwe, ndi zina za gawo lililonse la makina. Kutentha kosiyana kungapangitse malo enieni a olamulira aliyense kusintha, zomwe zingasokoneze kulondola kwa workpiece yomwe ikupangidwa. Kusintha kwenikweni kwa mtengo uku kungathe kuthetsedwa ndi chipukuta misozi cha kutentha. Zokhotakhota zolakwika za axis iliyonse pa kutentha kosiyana zimatha kufotokozedwa. Kuti nthawi zonse mupereke ndalama zolipirira kukulitsa kwamafuta moyenera, kufunikira kwa chipukuta misozi, malo owerengera komanso magawo ang'onoang'ono a gradient angle ayenera kusamutsidwa mosalekeza kuchokera ku PLC kupita ku ulamuliro wa CNC pogwiritsa ntchito midadada. Zosintha zosayembekezereka za parameter zimachotsedwa zokha ndi makina owongolera kuti apewe kulemetsa makina ndikuyambitsa ntchito zowunikira.