Fillet quenching technology ntawm crankshaft

2020-07-07

Lub crankshaft yog ib qho tseem ceeb tshaj plaws nyob rau hauv lub internal combustion engine, thiab nws cov kev pab cuam lub neej feem ntau txiav txim lub neej kev pab cuam ntawm lub internal combustion engine. Xyoo 1920, Lub Tuam Txhab American Clark tau siv cov cuab yeej induction hardening uas tau tsim tsis ntev los no rau crankshaft phau ntawv xov xwm hardening, uas zoo heev txhim kho kev puas tsuaj ntawm lub crankshaft, yog li txhim kho lub neej ua haujlwm ntawm lub cav combustion.

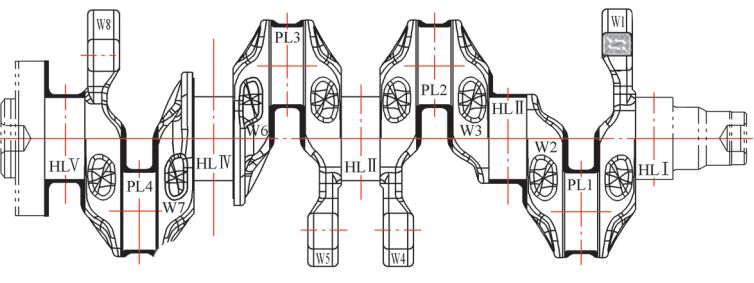

Nyob rau hauv xyoo tsis ntev los no, qaug zog tawg ntawm lub crankshaft tau dhau los ua qhov tseem ceeb, thiab qhov kev qaug zog feem ntau tshwm sim ntawm cov ces kaum ntawm lub crankshaft ntawm cov ntawv txuas txuas. Vim li no, ntau lub tuam txhab tau npaj cov kev cai los txhim kho lub zog qaug zog ntawm lub crankshaft. Tus yuam sij rau kev txhim kho crankshaft qaug zog lub zog yog kom cov residual compressive kev nyuaj siab ntawm lub crankshaft fillet. Induction hardening ntawm crankshaft fillets (nrog rau cov ntawv xov xwm) yog txoj kev nyiam kom tau txais qhov loj seem compressive stresses ntawm> 600MPa rau fillets. Ib lub tuam txhab Nyij Pooj tau ua ntau qhov kev sim ua rau qaug zog ntawm lub tshuab hluav taws xob sab hauv combustion crankshaft. Qhov kev sim ua pov thawj tias qhov sib npaug induction hardened crankshaft muaj lub zog siab tshaj plaws (996MPa), qhov sib npaug dov crankshaft qaug zog yog thib ob (890MPa), thiab nitrided crankshaft yog thib peb (720MPa). Cov tuam txhab Asmeskas kuj muaj cov ntaub ntawv zoo sib xws. Crankshaft fillet quenching feem ntau siv "ib nrab tig inductor" quenching, tseem hu ua Elotherm (Elotherm) quenching method. Nws yog hais tias lub sensor yog buckled nyob rau hauv phau ntawv journal, thiab lub crankshaft yog rhuab thiab dej quenched thaum lub sij hawm tig (tseem muaj ib rooj plaub uas lub crankshaft phau ntawv yog rhuab mus rau lub quenching kub thiab ces tig mus rau hauv lub pas dej ua ke kom txias thiab quenching). Txoj kev no tsis tsuas yog yooj yim rau kev nkag thiab tawm ntawm lub crankshaft sensor, yooj yim rau kev txiav txim ntawm cov cuab yeej quenching, tab sis kuj daws cov roj qhov tawg, qhov tsis sib xws ntawm qhov chaw hardened, qhov tsis sib xws ntawm cov txheej txheem hardened teeb meem xws li loj. deformation.

Cov neeg hauv kev lag luam feem ntau ntseeg tias Eluosen quenching txoj kev yog ib qho kev nce qib hauv crankshaft induction quenching technology. Cov ntaub ntawv qhia tias induction hardening ntawm crankshaft cov ntaub ntawv tuaj yeem ua rau lub cev muaj zog mus txog 8000 xuab moos, thaum induction quenching ntawm cov ntawv xov xwm thiab cov fillets tuaj yeem ua rau lub cev muaj zog mus txog 10,000 teev. Cov thev naus laus zis tseem ceeb uas yuav tsum tau daws kom ua tiav fillet quenching yog lub zog faib tshuab. Crankshaft "ib nrab tig inductor" quenching muaj ntau yam thev naus laus zis, xws li zaus hloov hluav taws xob, quenching tshuab cuab yeej thiab inductor, thiab lwm yam. Cov thev naus laus zis no kuj tseem ceeb heev, tab sis cov thev naus laus zis no tau pib daws hauv kuv lub teb chaws thaum xyoo 1980s.

Obviously, quenching cua sov ntawm lub crankshaft fillet yuav tsum tau nqa tawm tsis tu ncua. Lub zog cua sov ntawm sab hauv ntawm lub crank thiab sab nraud ntawm lub crank yuav tsum tau hloov, uas yog, lub zog ntawm sab hauv ntawm lub crank yuav tsum loj, thiab lub zog ntawm sab nraud ntawm lub crank yuav tsum me me. Lub tshuab no hu ua fais fab kev faib tshuab. Lub kaum sab xis ntawm qhov loj thiab me crankshafts yog quenched. Lub tshuab yog muab 100% lub zog thaum cua sov sab hauv ntawm lub crank, thiab 60% (los yog 70%) lub zog thaum cua sov sab nraud ntawm lub crank, thiab raws li lub crankshaft rotates, lub kaum sab xis nce (los yog txo) los ntawm ib tug npaum li cas. txhua 15 ° Lub zog.