Piston rings muaj ntau yam khoom siv thiab cov khoom sib txawv. Kev xaiv cov khoom siv lub nplhaib piston yuav tsum xav txog nws cov kev pabcuam, kev ua haujlwm, lub nplhaib hom thiab lwm yam. Feem ntau hais lus, piston nplhaib cov khoom ntawm lub cav combustion yuav tsum ua tau raws li cov hauv qab no:

1. Lub zog muaj zog txaus ntawm qhov kub thiab txias

2. Hnav tsis kam thiab tsis tshua muaj kev sib txhuam coefficient

3. Nws tsis yog yooj yim los tsim adhesion thiab yooj yim khiav hauv

4. Kev ua haujlwm yog yooj yim thiab tus nqi pheej yig

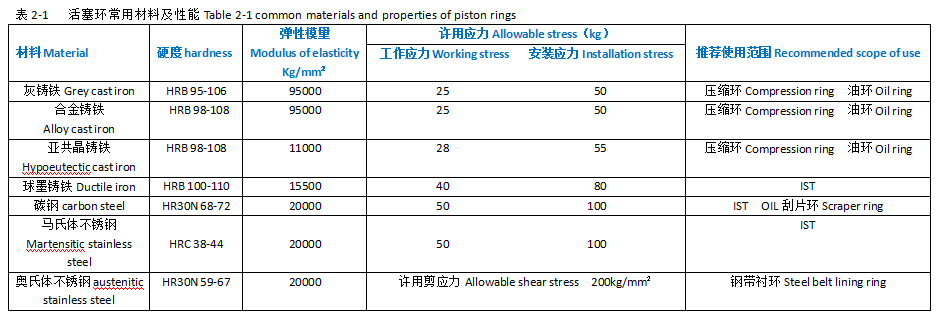

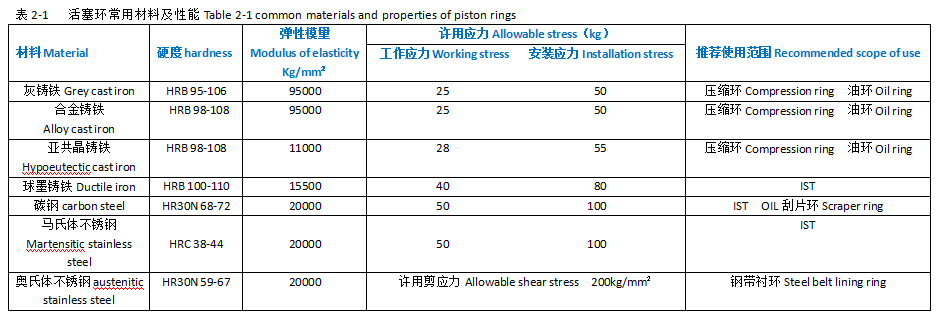

Nyob rau hauv txoj kev no, cov khoom siv piston nplhaib yuav tsum muaj qee lub zog, hardness, elasticity, hnav tsis kam (nrog rau cov roj cia), corrosion resistance, thermal stability thiab processability. Tam sim no, cov khoom siv ntawm lub nplhaib piston feem ntau yog cam khwb cia hlau. Nrog lub zog ntawm lub cav, muaj kev hloov pauv ntawm grey cam khwb cia hlau mus rau malleable cam khwb cia hlau, nodular cam khwb cia hlau thiab hlau. Saib cov lus 2-1 rau cov khoom siv thiab cov khoom siv.

Table 2-1 cov khoom siv thiab cov khoom ntawm piston rings

Txawm li cas los xij, niaj hnub no cov lus qhia tsis yog lub nplhaib piston ntawm cov khoom siv sib xws, tab sis cov hlau ceramic puas zaj duab xis piston nplhaib (ceramic infiltrated piston nplhaib lossis ceramic hlau piston nplhaib rau luv), hereinafter hu ua hlau ceramic piston nplhaib.

Cermet piston rings yog tsim los ntawm infiltrating boron nitride (ib feem ntawm cubic boron nitride) ceramics nrog * self-lubricating muaj nuj nqi mus rau hauv lub nto txheej ntawm piston nplhaib kev sib txhuam khub ntawm qhov kub thiab txias (qis dua 200 ℃) los ntawm kev siv lub ntiaj teb no * advanced "plasma tshuaj vapor deposition technology", thiaj li hais tias cov txheej txheem nto ua hauj lwm ntawm piston rings yog ceramic. Cov piston rings tom qab ceramic infiltration muaj qhov hnav tsis kam, hnav tsis kam thiab corrosion kuj, Yog li ntawd, kev pabcuam lub neej ntawm lub nplhaib piston tuaj yeem txhim kho. Ceramic composite yog infiltrated rau saum npoo ntawm piston nplhaib los ntawm plasma tshuaj vapor deposition, uas yog txawv los ntawm cov ceramic spraying txheej txheem rau saum npoo ntawm lwm piston rings. Cov txheej txheem txheej txheem no tuaj yeem ua rau cov khoom siv sib xyaw ceramic muaj lub zog ruaj khov nrog lub nplhaib piston tsis tawg thiab poob.

Tsis tas li ntawd, cermet composite txheej muaj cov qauv hluav taws xob zoo ib yam li rhodium, yog li nws tuaj yeem nqa tawm combustion Catalysis hauv lub cav thiab txo qis cov ntsiab lus ntawm CO thiab HC. Yog li ntawd, ceramic impregnated piston rings kuj muaj cov nyhuv catalytic.

"Cermet composite zaj duab xis" thev naus laus zis dhau qhov kev ntsuas * hauv xyoo 1997.

Ceramic impregnated piston rings tau dav siv nyob rau hauv loj cav nroj tsuag nrog zoo daim ntawv thov.

Nws tsim "ua haujlwm ceramics" sib xyaw nrog cov hlau, uas muaj cov yam ntxwv zoo ntawm qhov tawv tawv, tsis muaj kev sib txhuam coefficient, hnav txo thiab ua haujlwm ntev.

Ntawm qhov kub qis (qis dua 200 ℃), nitride (cov khoom siv sib xyaw ceramic) tau nkag mus rau hauv cov cuab yeej nto los ntawm plasma tshuaj vapor deposition.

Nta:

1. Tsawg kub loj hlob. Thaum cov zaj duab xis-forming kub yog qis dua 200 ℃, nws yuav tsis ua puas lub substrate thiab nto ntawm lub workpiece, los yog deform lub workpiece, thiab yuav tsis cuam tshuam rau lub machining raug thiab sib dhos ua tau zoo.

2. Kev sib txuas yog ruaj khov. Vim hais tias cov hlau diffuses nrog boron nitride thiab cubic boron nitride nyob rau hauv lub xeev ntawm lub tshuab nqus tsev plasma los tsim dumping functionally gradient cov ntaub ntawv, cov composite films yuav tsis tev tawm ntawm kub los yog cuam tshuam.

3. Ob leeg hardness thiab toughness yog txhim kho. Vim yog ob-theem diffusion ntawm cov zaj duab xis thiab hlau los tsim inclined gradient functional khoom, nws tsis tsuas yog plays lub luag hauj lwm ntawm ruaj khov ua ke ntawm kev hloov txheej, tab sis kuj pab txoj kev sib raug zoo zog, tensile muaj peev xwm thiab dabtsi yog khoov tsis kam ntawm ceramic, thiab nws toughness. tshaj qhov ntawm ceramic nws tus kheej.

4. Zoo hnav tsis kam ntawm qhov kub thiab txias. Cov txiaj ntsig kev sim qhia tau hais tias piv nrog chromium plating, hardness ntawm cov zaj duab xis sib xyaw ua ke nce siab heev nrog qhov nce ntawm qhov kub thiab txias hauv ib puag ncig ntawm 250 ℃ - 350 ℃, thiab cov tawv tawv tawv nce ntau dua li hv210, thaum lub zog chromium txo qis tom qab. 250 ℃, thiab txo qis li ntawm hv110 ntawm 350 ℃. Yog li, piv nrog cov khoom ua haujlwm tsis muaj cov yeeb yaj kiab sib xyaw, cov ceramic plated workpiece tau zoo dua hnav tsis kam hauv qhov kub thiab txias.

5. Muaj zog oxidation tsis kam. Cov txiaj ntsig kev sim qhia tau hais tias cov zaj duab xis sib xyaw tseem muaj qhov zoo oxidation tsis kam thiab acid-base tsis kam thaum qhov kub siab tshaj 1000 ℃.

6. Nws muaj kev ua haujlwm ntawm oxidation thiab catalysis. Thaum cov ceramic nkag mus rau hauv cov hlau nto, qhov tsim nyog ntawm cov khoom siv hluav taws xob tsim tawm, uas ua rau cov yeeb yaj kiab sib xyaw muaj cov oxidation catalytic cuam tshuam rau CO thiab HC, thiab txo qis cov pa paug tawm ntawm lub cav.

7. Zoo winding thiab plating kev ua tau zoo. Cov yeeb yaj kiab sib xyaw yog cov tshuaj vapor deposition, yog li cov yeeb yaj kiab sib xyaw tuaj yeem loj hlob txhua qhov chaw uas muaj roj tuaj yeem dhau los, thiab cov txheej txheem ua haujlwm tsis txwv los ntawm cov duab thiab txoj haujlwm ntawm lub workpiece.

8. Dav daim ntawv thov teb. Ntxiv nrog rau kev siv rau lub cav, cov yeeb yaj kiab sib xyaw kuj tseem tsim nyog rau kev sib txhuam ntawm ntau lub cav, qhov kub thiab txias thiab corrosion-resistant qhov chaw, ntau yam cuab yeej txiav thiab pwm, thiab tuaj yeem hloov mus rau ntau yam hlau lossis cov khoom tsis yog hlau los ntawm cov txheej txheem sib txawv.