Loaʻa i nā apo piston nā ʻano mea like ʻole a me nā waiwai like ʻole. Pono e noʻonoʻo ke koho ʻana i ke ʻano o ke apo piston i kona kūlana lawelawe, nā koi hana, ke ʻano apo a me nā mea ʻē aʻe. ʻO ka ʻōlelo maʻamau, ʻo ka piston ring material o ka mīkini hoʻopau i loko e hoʻokō i nā koi aʻe:

1. Kiʻekiʻe lawa mechanical ikaika ma kiʻekiʻe wela

2. E hoʻohana i ke kūpaʻa a me ka helu haʻahaʻa haʻahaʻa

3. ʻAʻole maʻalahi ka hana adhesion a maʻalahi ke holo i loko

4. He mea maʻalahi ka hanaʻana a he maʻalahi ke kumukūʻai

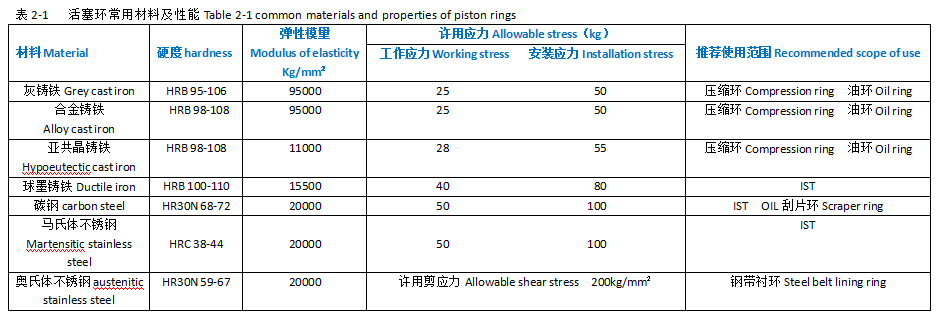

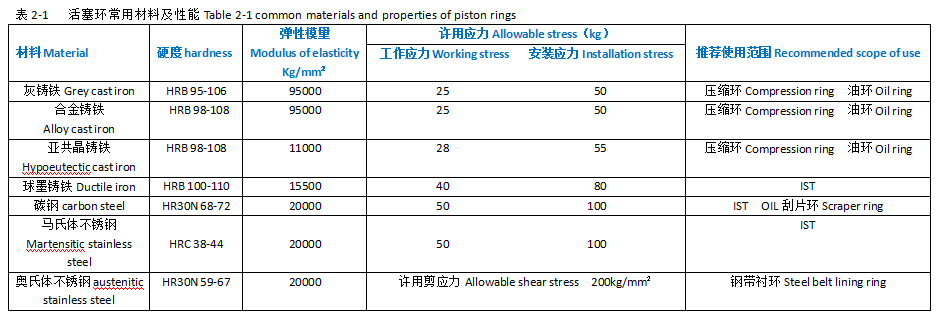

Ma kēia ala, koi ʻia ka mea kani piston e loaʻa i kekahi ikaika, paʻakikī, elasticity, pale ʻana (me ka waiho ʻana o ka aila), pale ʻana i ka corrosion, thermal stability and processability. I kēia manawa, ʻo ka mea o ke apo piston ka hao nui. Me ka hoʻoikaika ʻana o ka ʻenekini, aia ke ʻano o ka hoʻololi ʻana mai ka hao hina hina i ka hao malleable, ka hao nodular a me ke kila. E nānā i ka papa 2-1 no nā mea maʻamau a me nā waiwai.

Papa 2-1 mau mea ma'amau a me na waiwai o na apo piston

Eia nō naʻe, ʻaʻole ʻo ke apo piston o nā mea maʻamau ka hoʻolauna ʻana i kēia lā, akā ʻo ke apo piston kiʻi ʻoniʻoni metala (ceramic infiltrated piston ring a i ʻole ceramic metal piston ring no ka pōkole), ma hope mai i kapa ʻia ʻo ke apo piston ceramic.

Hana ʻia nā apo piston Cermet e ka hoʻokomo ʻana i ka boron nitride (kahi hapa o ka cubic boron nitride) nā seramika me ka * hana hoʻomaʻamaʻa ponoʻī i loko o ka ʻili o ke apo piston friction pair i ka haʻahaʻa haʻahaʻa (ma lalo o 200 ℃) ma ka hoʻohana ʻana i ka honua * holomua "plasma chemical vapor. ʻenehana deposition", no laila he seramika ka papa hana o nā apo piston. ʻO nā apo piston ma hope o ka infiltration seramika he maikaʻi ke pale ʻana i ka lole, ke kūpaʻa a me ka pale ʻana i ka corrosion, no laila, hiki ke hoʻomaikaʻi ʻia ke ola lawelawe o ke apo piston. Hoʻokomo ʻia ka ceramic composite i loko o ka ʻili o ke apo piston e ka hoʻoheheʻe ʻana i ka mahu kemika plasma, ʻokoʻa ia mai ke kaʻina hana hoʻoheheʻe ceramic ma ka ʻili o nā apo piston ʻē aʻe. Hiki i kēia ʻano kaʻina hana ke hana i ka mea hana seramika i hoʻopaʻa paʻa i ka ikaika me ka ʻili o ke apo piston me ka haki ʻole a hāʻule.

Eia kekahi, ʻo ka cermet composite layer he ʻano uila like me ka rhodium, no laila hiki iā ia ke hoʻokō i ka Combustion Catalysis i loko o ka mīkini a hoʻemi nui i ka ʻike o ka hoʻokuʻu ʻana o CO a me HC. No laila, loaʻa i nā apo piston ceramic impregnated ka hopena catalytic.

Ua hala ka ʻenehana "Cermet composite film" i ka * appraisal ma 1997.

Ua hoʻohana nui ʻia nā apo piston Ceramic impregnated i nā mea kanu mīkini nui me ka hopena noi maikaʻi.

Hoʻokumu ia i nā "mea hana ceramics" i hui pū ʻia me nā metala, nona nā hiʻohiʻona koʻikoʻi o ka paʻakikī o ka ʻili kiʻekiʻe, haʻahaʻa friction coefficient, hoʻemi ʻaʻahu a me ke ola lawelawe lōʻihi.

Ma ka wela haʻahaʻa (ma lalo o 200 ℃), ua hoʻokomo ʻia ka nitride (composite ceramic material) i loko o ka ʻili o ka mea hana e ka hoʻoheheʻe ʻana i ka mahu kemika plasma.

Nā hiʻohiʻona:

1. Haʻahaʻa wela ulu. Ke emi ka mahana o ka hana kiʻiʻoniʻoni ma lalo o 200 ℃, ʻaʻole ia e hōʻino i ka substrate a me ka ʻili o ka mea hana, ʻaʻole hoʻi e hoʻololi i ka mea hana, ʻaʻole ia e hoʻopilikia i ka pololei o ka mīkini a me ka hana hui.

2. Paʻa ka pilina. Ma muli o ka laha ʻana o ka metala me ka boron nitride a me ka cubic boron nitride i ka mokuʻāina o ka vacuum plasma e hana i ka hoʻolei ʻana i nā mea gradient functionally, ʻaʻole e ʻili nā kiʻi ʻoniʻoni i ka wela kiʻekiʻe a i ʻole ka hopena.

3. Hoʻomaikaʻi ʻia ka paʻakikī a me ka paʻakikī. Ma muli o ka diffusion ʻelua-phase o ka kiʻiʻoniʻoni composite a me ka metala e hana i nā mea hana gradient gradient, ʻaʻole wale ia e pāʻani i ke kuleana o ka hui paʻa ʻana o ka papa hoʻololi, akā hoʻomaikaʻi hoʻi i ka ikaika hoʻopaʻa ʻana, ka mana tensile a me ke kūlou ʻana o ka ceramic, a me kona paʻakikī. ʻoi aku ma mua o ka seramika ponoʻī.

4. ʻAʻahu maikaʻi ke kū'ē i ka wela kiʻekiʻe. Hōʻike nā hopena hoʻokolohua i ka hoʻohālikelike ʻia me ka chromium plating, piʻi nui ka paʻakikī o ka kiʻiʻoniʻoni composite me ka piʻi ʻana o ka mahana ma ke kaiapuni o 250 ℃ - 350 ℃, a piʻi aʻe ka paʻakikī o ka ʻili ma mua o ka hv210, aʻo ka chromium paʻakikī e emi nui ma hope. 250 ℃, a emi iho ma kahi o hv110 ma 350 ℃. No laila, ke hoʻohālikelike ʻia me ka mea hana me ka ʻole o ka hoʻopaʻa ʻia ʻana o ke kiʻiʻoniʻoni, ʻoi aku ka maikaʻi o ka pale ʻana o ka mea hana seramika ma ke ʻano wela wela.

5. Ke kū'ē i ka oxidation ikaika. Hōʻike nā hopena hoʻokolohua ʻoi aku ka maikaʻi o ke kiʻi ʻoniʻoni i hoʻopaʻa ʻia a me ke kūpaʻa acid-base ke ʻoi aku ka mahana ma mua o 1000 ℃.

6. Loaʻa iā ia ka hana o ka oxidation a me ka catalysis. Ke komo ka ceramic i loko o ka ʻili metala, hoʻokumu ʻia kahi helu kūpono o ka hakahaka electron, kahi e loaʻa ai ka hopena catalytic oxidation ma ka CO a me HC i ke kiʻi ʻoniʻoni, a hoʻemi nui i ka pollution exhaust emission o ka mīkini.

7. ʻO ka wili maikaʻi a me ka hana plating. ʻO nā kiʻiʻoniʻoni i hoʻopaʻa ʻia he hoʻoheheʻe kemika, no laila hiki ke hoʻoulu ʻia nā kiʻiʻoniʻoni composite ma nā wahi āpau e hele ai ke kinoea, a ʻaʻole kaupalena ʻia nā kūlana hana e ke ʻano a me ke kūlana o ka mea hana.

8. Nā kahua noi ākea. Ma waho aʻe o ka hoʻohana ʻia ʻana i ka ʻenekini, ua kūpono ke kiʻi ʻoniʻoni i nā hui friction o nā mīkini like ʻole, nā ʻāpana kiʻekiʻe a me ka corrosion-resistant, nā mea ʻoki like ʻole a me nā mold, a hiki ke hoʻololi i nā mea metala a i ʻole nā mea metala ma o nā palena kaʻina hana like ʻole.