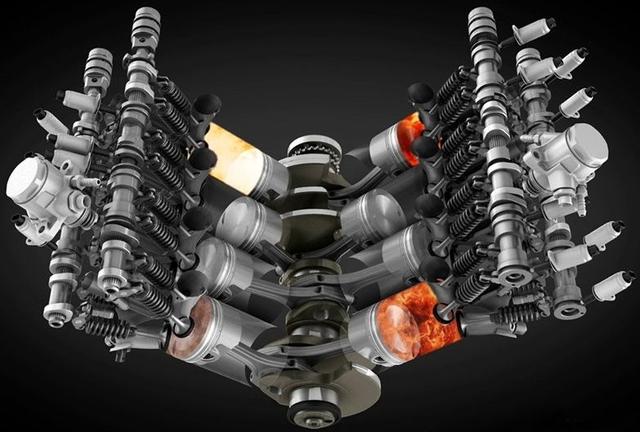

An raba tubalan silinda na injin mai zuwa simintin ƙarfe da simintin aluminum. Kwatanta fa'idodi da rashin amfanin aluminum Silinda da simintin simintin simintin ƙarfe:

1) Nauyi

Ƙayyadaddun nauyin aluminum ya fi na baƙin ƙarfe na simintin gyare-gyare, kuma shingen silinda na aluminum ya fi sauƙi a ƙarƙashin yanayin biyan bukatun ƙarfin. Injin yana da haske, wanda ke da tasiri mai kyau akan rarraba nauyin abin hawa, kuma nauyin abin hawa yana da sauƙi. Saboda haka, a wannan lokaci, aluminum cylinders rinjaye.

2) Juzu'i

Saboda wannan dalili, ƙayyadaddun nauyin aluminum ƙanƙanta ne, kuma ƙarfin tsarin aluminum kowace juzu'in juzu'i bai kai na simintin ƙarfe ba, don haka silinda na aluminum yawanci ya fi girma a girma. Tushen Silinda na EA113/EA888 yana da nisan tsakiya-zuwa-Silinda na 88mm, yayin da sigar data kasance tana da diamita na Silinda har zuwa 82.5mm. Ban da tashar ruwa mai sanyaya, bangon Silinda a zahiri yana da bakin ciki sosai. Ta wannan hanyar, injin ɗin gabaɗaya yana da ɗanɗano sosai kuma ƙarami ne. Aluminum cylinders sun fi wuya a cimma wannan sakamako. A wannan lokaci, tubalin silinda na simintin simintin ya mamaye. [Kari: Ƙarfin simintin ƙarfe na simintin ductile zai iya zama fiye da 1000MPa, yayin da ƙarfin tensile na jirgin sama na 7075 aluminum gami shine 524MPa, ƙarancin ƙarfe shine 7.85, kuma yawan aluminum shine 2.7. Don haka, don samun ƙarfi iri ɗaya, ana buƙatar ƙarar ƙarar allo na aluminium da kusan ɗaya. Lokaci, amma nauyin yana kusan 40% sauƙi.

3) Juriya na lalata da ƙarfi

Aluminum yana da sauƙin amsawa ta hanyar sinadarai da ruwan da ake samarwa yayin konewa, kuma juriyar lalatarsa ba ta kai na simintin silinda na simintin ƙarfe ba, musamman ga injunan da ke da caji mai ƙarfi da matsi. Kuma ƙarshe na baya game da ƙarar, a gefe guda, lokacin da buƙatun injin ku ba su da ƙanƙanta, yawanci yana da wahala a cimma ƙarfin tubalan silinda na simintin simintin simintin ƙarfe tare da shingen silinda na aluminum. Don haka, yawancin injuna masu girma da yawa suna amfani da tubalan simintin ƙarfe, kamar (kafin ƙarni na 9) EVO's 286hp 2.0L I4 (4G63), wanda koyaushe ake jefa tubalan ƙarfe. Babban iyakar gyare-gyarensa kuma sananne ne. Idan aka yi amfani da silinda na aluminum, mai yiwuwa ba zai zama da sauƙi ba. A wannan lokaci, tubalin silinda na simintin simintin ya mamaye.

4) Farashin

Kudin yana da dabi'a cewa silinda na aluminum ya fi tsada, kuma babu wani abin da zai bayyana. A wannan lokaci, tubalin silinda na simintin simintin ya mamaye.

5) Juriya da fashewa da zafi

Aluminum yana gudanar da zafi da sauri, don haka yana da kyakkyawan aikin sanyaya, wanda zai iya taimakawa injin ya rage yiwuwar konewa mara kyau. A daidai wannan rabon matsawa, injinan silinda na aluminium na iya amfani da ƙananan man fetur fiye da injunan silinda na simintin ƙarfe. A wannan gaba, shingen silinda na aluminum yana da rinjaye.

6) Ƙwaƙwalwar ƙira

Don rage rashin ƙarfi na sassa masu juyawa da haɓaka saurin juyawa da saurin amsawa, yawancin pistons suna amfani da alloy na aluminum azaman abu. Idan bangon Silinda kuma an yi shi da aluminum, ƙimar juzu'i tsakanin aluminium da aluminium yana da girma, wanda ke tasiri sosai ga aikin injin. Simintin ƙarfe ba shi da irin wannan matsala. A wannan lokaci, tubalan silinda baƙin ƙarfe ya mamaye. [Ƙari: wasu injunan da ake kira "all-aluminum" suma suna amfani da simintin ƙarfe na silinda.

a ƙarshe:

Amfanin aluminum: nauyi mai sauƙi, mai kyau zafi mai zafi;

Amfanin ƙarfe: arha kuma mai dorewa.