Injin Silinda block sarrafa da tsarinsa

2020-04-22

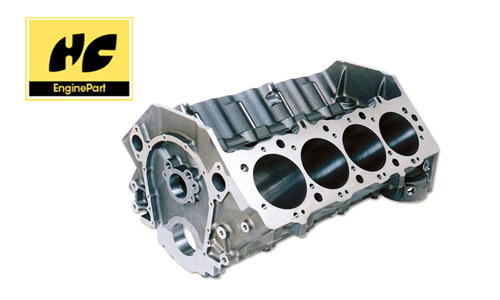

A matsayinsa na fasahar kere-kere na motoci, sarrafa toshewar injina sannu a hankali yana shiga cikin manyan kamfanoni. Katangar injin wani bangare ne na bakin ciki mai katanga kuma mai ratsa jiki, wanda ke bukatar cikakken daidaitattun hanyoyin sarrafawa daban-daban, kuma ingancin sarrafa bangaren yana shafar aikin injin kai tsaye.

Toshewar injin wani sashe ne mai kama da akwati tare da sirara mai katanga mai hadadden tsari, wanda ke da saukin lalacewa yayin sarrafa shi, wanda ke bukatar tabbatar da ingancinsa. A halin yanzu, sarrafawa da samar da injuna galibi suna nufin kammala samarwa akan layukan sassauƙa waɗanda ke ƙarƙashin ikon cibiyoyin injin CNC. Wannan fasaha yana da manyan buƙatu don fasahar sarrafa kansa da ƙarancin farashin samarwa. Bugu da ƙari, a cikin aiki na shingen silinda, daidaiton kowane hanyar haɗi ya kamata ya kasance mai girma sosai, in ba haka ba yana da wuya a cika ka'idodin wannan tsari. Mai zuwa shine takamaiman tsarin fasaha na sarrafa Silinda:

1. Silinda surface aiki

Abubuwan sarrafa saman silinda an raba su zuwa sarrafa jirgin sama da sarrafa tazara. Mashin din jirgin dai ya kunshi nakakar karshen fuska, kamar: sarrafa fuskar sama, kasa da gaba da bayanta. Yin aiki da ɓarna sau da yawa yana buƙatar matakai irin su m, honing, hakowa, reaming, da kuma tapping, ciki har da hollowing jaket ruwa, hawa ramuka, haɗa ramukan, piston Silinda ramukan, mai ramuka, da dai sauransu.

2. Silinda machining tsari

Za a iya raba tsarin mashin ɗin tubalan silinda kusan zuwa shirye-shirye huɗu: babban sarrafa bayanan martaba, sarrafa ginshiƙi na babban rami, dubawar tsaftacewa, da sarrafa tsari na taimako. Shirye-shirye daban-daban suna da alhakin fannoni daban-daban da matsayi daban-daban. Misali: wani sashe na shirin yana amfani da cikakken hanyar saka fil biyu, wasu kuma suna ɗaukar madaidaicin hanyar 3 one 2 one] cikakkiyar hanyar sakawa. Bugu da ƙari, wurin sanyawa ta hanyoyi daban-daban kuma yana da bambanci tsakanin ƙasa da ƙarshen. A cikin machining na silinda block, yana da matukar muhimmanci tsari ga machining na kasa da kuma karshen saman na Silinda block.

3. Silinda machining matakin rabo

Silinda machining za a iya raba biyu kayayyaki, roughing da karewa. Kowane module za a iya raba kashi biyu. Duk layin samarwa ya kasu kashi uku: naúrar roughing, Semi-finishing unit da kuma karewa naúrar. Ga kowane mataki, samfurin yana buƙatar a sanya shi gwargwadon buƙatu kuma ya kamata a aiwatar da samarwa mai ma'ana.