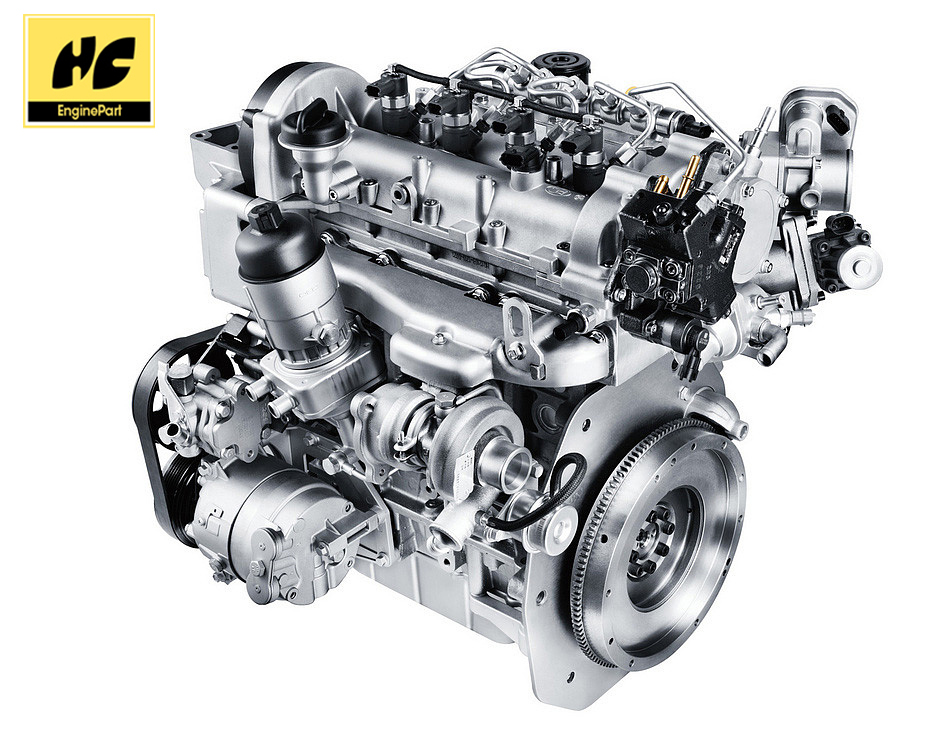

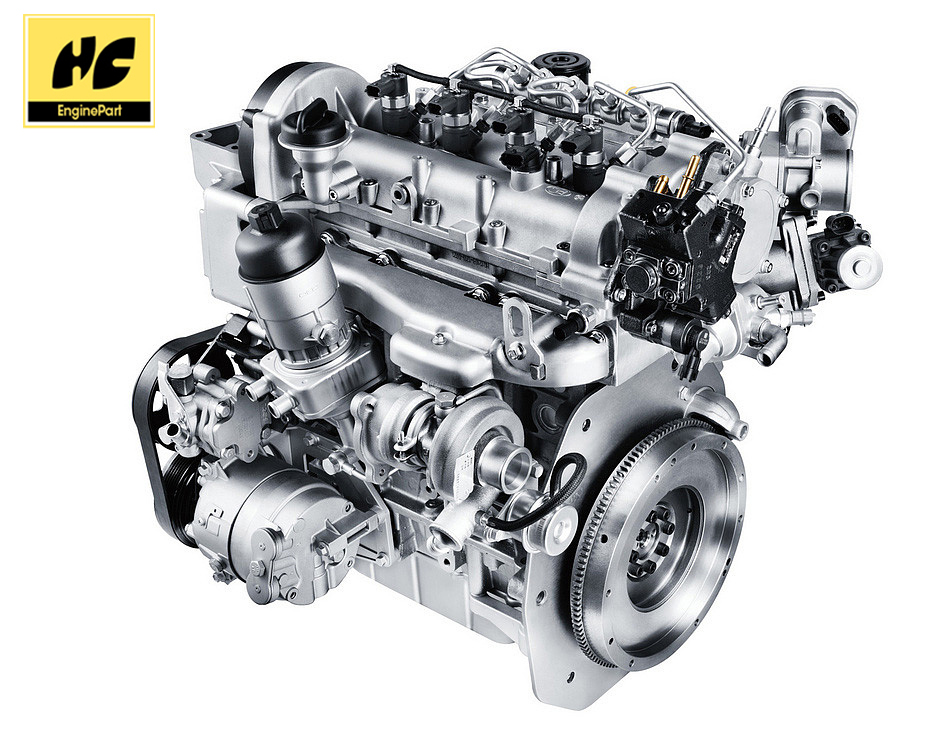

A halin yanzu, akwai manyan injunan motoci iri biyu: injinan simintin ƙarfe da injunan aluminum. To, wanne daga cikin waɗannan injunan abu biyu ne ya fi kyau a yi amfani da su? Menene bambanci tsakanin injinan biyu? A gaskiya ma, kusan dukkanin kayan injin silinda an yi su ne da aluminum, saboda shugabannin silinda na aluminum suna da mafi kyawun aikin watsawar zafi. Shugaban Silinda na injin simintin simintin simintin simintin simintin ƙarfe ne a haƙiƙanin alloy na aluminum, amma shingen Silinda an jefa baƙin ƙarfe.

Idan aka kwatanta da injunan aluminium, tubalin silinda na injin simintin ƙarfe yana da ƙarfin lodin zafi mai ƙarfi, wanda ya fi dacewa don ƙara ƙarfin injin. Misali, a ƙarƙashin tasirin turbocharging, injin simintin ƙarfe na 1.5L na ƙaura zai iya isa ainihin buƙatuwar 2.0L; yayin da injin all-aluminum ba zai iya cika irin wannan buƙatu ba. A halin yanzu, manyan motoci kaɗan ne kawai ke amfani da injin aluminum.

Bugu da kari, dukkan injunan aluminium suna da saurin kamuwa da halayen sinadarai tare da ruwa yayin aiki, kuma juriyar lalatarsu ta yi kasa da na simintin simintin ƙarfe, kuma ƙarfin silinda na aluminum ya yi ƙasa da na simintin ƙarfe. Saboda haka, m duk turbocharged injuna aka jefa baƙin ƙarfe tubalan. Yana da kyau a faɗi cewa tubalan silinda na simintin simintin yana da ƙarfin gyare-gyare wanda injin jikin aluminum ba shi da shi.

Sabanin haka, babbar fa'idar duk injunan aluminium shine cewa a wannan ƙaura, nauyin dukkan injina na aluminum ya kai kilogiram 20 fiye da na injin simintin ƙarfe. Bugu da ƙari, tasirin zafi na duk-aluminum engine yana da kyau fiye da na simintin simintin ƙarfe, wanda zai iya inganta aikin aikin injiniya da kuma taimakawa wajen tsawaita rayuwar injin.

A halin yanzu, kusan dukkanin pistons na injin ana yin su ne da gariyar aluminum. Idan kayan bangon Silinda kuma duk aluminum ne, ƙimar juzu'i tsakanin aluminium da aluminum ya fi girma, wanda zai shafi aikin injin. Wannan shine dalilin da ya sa kullun simintin ƙarfe na simintin gyare-gyaren keɓaɓɓu a cikin jikin silinda na dukkan injunan aluminum.

A gaskiya ma, a taƙaice, duk injin aluminum yana da halaye na aiki mai sauƙi, nauyi mai sauƙi, da kuma zafi mai kyau. Abubuwan fa'idodin injunan ƙarfe na simintin ƙarfe suna nunawa a cikin juriya mai ƙarfi, juriya mai zafi, juriya na lalata, juriya na lalacewa da ƙarancin farashi.