Zoben Piston suna da nau'ikan kayan aiki iri-iri da kaddarorin daban-daban. Zaɓin kayan zoben piston yakamata yayi la'akari da yanayin sabis ɗin sa, buƙatun aikin aiki, nau'in zobe da sauran abubuwan. Gabaɗaya magana, kayan zoben piston na injin konewa na ciki zai cika buƙatu masu zuwa:

1. Babban isasshen ƙarfin inji a babban zafin jiki

2. Sa juriya da ƙananan juzu'i

3. Ba shi da sauƙi don samar da mannewa da sauƙin shiga ciki

4. Yin aiki yana dacewa kuma farashin yana da arha

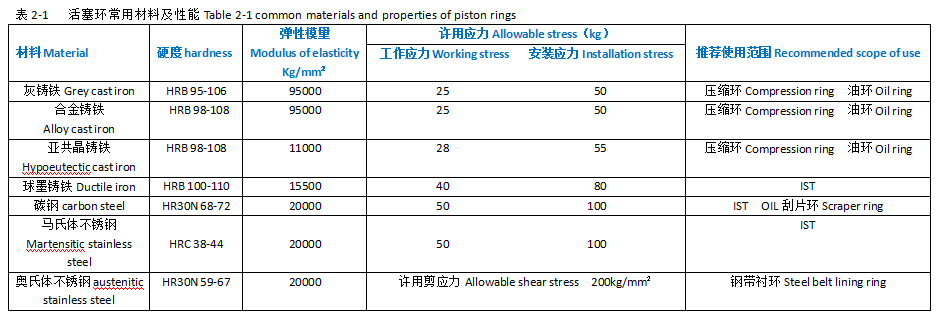

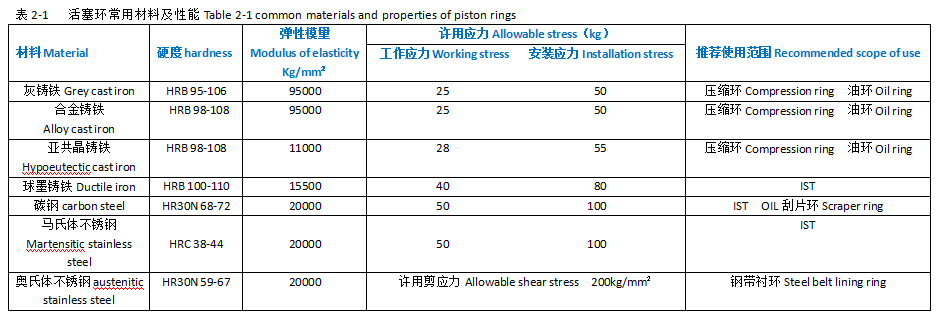

Ta wannan hanyar, ana buƙatar kayan zoben piston don samun takamaiman ƙarfi, taurin, elasticity, juriya (ciki har da ajiyar mai), juriya na lalata, kwanciyar hankali na thermal da aiwatarwa. A halin yanzu, kayan zoben piston galibi simintin ƙarfe ne. Tare da ƙarfafa injin, akwai yanayin canji daga ƙarfen simintin simintin toka zuwa simintin simintin ƙarfe, ƙarfen simintin nodular da ƙarfe. Dubi tebur 2-1 don kayan gama gari da kaddarorin.

Tebur 2-1 kayan gama gari da kaddarorin zoben piston

Duk da haka, gabatarwar yau ba zoben piston na kayan gama gari bane, amma ƙarfe yumbu hadadden fim ɗin piston zobe ( yumbu infiltrated piston zobe ko yumbu karfe fistan zobe a takaice), daga baya ake magana a kai da karfe yumbu piston zobe.

Ana yin zoben piston na Cermet ta hanyar shigar da boron nitride (ɓangare na cubic boron nitride) yumbu tare da * aikin sanya mai a cikin saman Layer na piston zoben gogayya a cikin ƙananan zafin jiki (ƙasa da 200 ℃) ta amfani da duniya * ci gaba "turin sinadarai na plasma fasahar hadawa", don haka aikin saman saman zoben piston ya zama yumbu. Ƙwayoyin piston bayan shigar da yumbu suna da juriya mai kyau, juriya da juriya na lalata, Saboda haka, za a iya inganta rayuwar sabis na zoben piston. An shigar da yumbu mai haɗe zuwa saman zoben piston ta hanyar tururin sinadarai na plasma, wanda ya bambanta da tsarin feshin yumbu a saman sauran zoben fistan. Wannan hanyar aiwatarwa na iya sanya kayan yumbu masu haɗaka su sami ƙarfin haɗin gwiwa tare da saman zoben piston ba tare da tsagewa da faɗuwa ba.

Bugu da kari, cermet composite Layer yana da tsarin lantarki mai kama da rhodium, don haka yana iya aiwatar da catalysis na konewa a cikin injin kuma yana rage fitar da abun ciki na CO da HC sosai. Saboda haka, yumbu impregnated piston zoben suma suna da tasirin gaske.

Fasahar "Cermet composite film" ta wuce * kimantawa a cikin 1997.

An yi amfani da zoben piston da ke ciki da yumbu a cikin manyan injiniyoyi tare da tasirin aikace-aikace mai kyau.

Yana samar da "aiki tukwane" tare da karafa, wanda yana da fitattun halaye na babban taurin saman, ƙarancin juzu'i, raguwar lalacewa da tsawon rayuwar sabis.

A ƙananan zafin jiki (ƙasa da 200 ℃), nitride (nau'in yumbura mai hade) yana shiga cikin saman kayan aiki ta hanyar jigilar sinadarai na plasma.

Siffofin:

1. Low zafin jiki girma. Lokacin da zafin jiki na fim ɗin ya kasance ƙasa da 200 ℃, ba zai lalata ƙasa da saman kayan aikin ba, kuma ba zai lalata kayan aikin ba, kuma ba zai shafi daidaiton machining da aikin taro ba.

2. Haɗin yana da ƙarfi. Saboda karfen yana yaduwa da boron nitride da cubic boron nitride a cikin yanayin vacuum plasma don samar da jujjuyawan kayan aikin gradient, fina-finan da aka haɗe ba za su bare a babban zafin jiki ko tasiri ba.

3. Duk taurin da taurin suna inganta. Saboda biyu-lokaci yadawa na hada fim da karfe don samar da karkata gradient aiki abu, shi ba kawai taka rawar da m hade da mika mulki Layer, amma kuma inganta bonding ƙarfi, tensile iya aiki da lankwasawa juriya na yumbu, da taurin. ya zarce na yumbun kanta.

4. Kyakkyawan juriya na lalacewa a babban zafin jiki. Sakamakon gwaji ya nuna cewa idan aka kwatanta da plating na chromium, taurin fim ɗin ya karu sosai tare da karuwar zafin jiki a cikin yanayin 250 ℃ - 350 ℃, kuma taurin saman yana ƙaruwa da fiye da hv210, yayin da chromium mai wuya ya ragu sosai bayan haka. 250 ℃, kuma yana raguwa da kusan hv110 a 350 ℃. Saboda haka, idan aka kwatanta da workpiece ba tare da hada fim plating, da yumbu plated workpiece yana da mafi alhẽri jure juriya a high zafin jiki yanayi.

5. Ƙarfin oxidation juriya. Sakamakon gwaji ya nuna cewa fim ɗin da aka haɗa har yanzu yana da juriya mai kyau na iskar shaka da juriya na tushen acid lokacin da zafin jiki ya fi 1000 ℃.

6. Yana da aikin oxidation da catalysis. Lokacin da yumbu ya shiga cikin saman ƙarfe, an samar da adadin da ya dace na guraben lantarki, wanda ke sa fim ɗin da aka haɗa ya sami tasirin oxidation catalytic akan CO da HC, kuma yana rage yawan gurɓataccen iska na injin.

7. Kyakkyawan iska da aikin plating. Fina-finan da aka haɗe su ne jigon tururin sinadarai, don haka za a iya shuka fina-finai masu haɗaka a duk inda gas zai iya wucewa, kuma yanayin sarrafa ba ya iyakance ta siffar da matsayi na aikin.

8. Faɗin aikace-aikacen filayen. Bugu da ƙari, ana amfani da shi ga injin, fim ɗin da aka haɗa kuma ya dace da nau'i-nau'i na nau'i-nau'i na injuna daban-daban, sassa masu zafi da lalata, daban-daban kayan aikin yankan da gyare-gyare, kuma zai iya dacewa da nau'i-nau'i na karfe ko kayan da ba na ƙarfe ba ta hanyar. sigogi daban-daban na tsari.